Embracing Technology in Scaffolding: A New Era of Efficiency

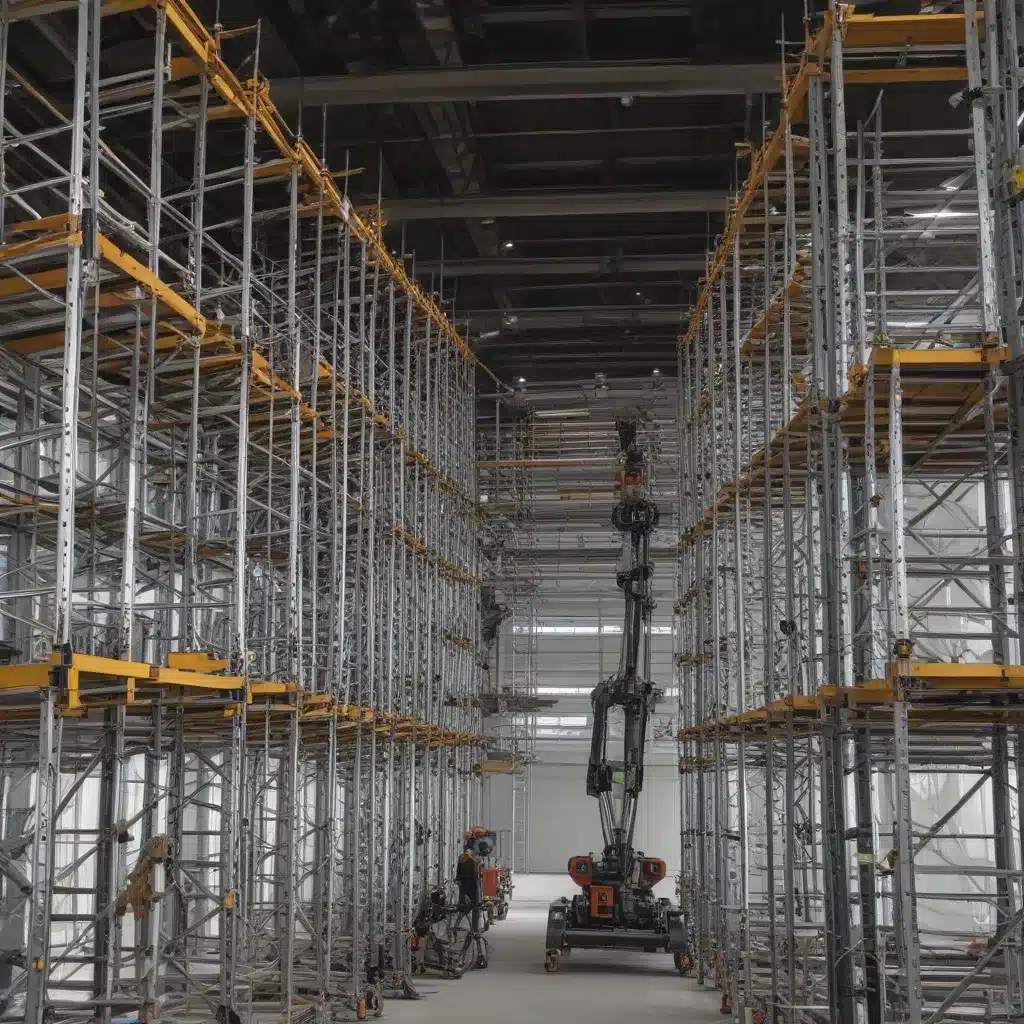

The construction industry in the United Arab Emirates (UAE) has undergone a remarkable transformation in recent years, with the adoption of cutting-edge technologies and innovative practices. One area that has been at the forefront of this digital revolution is the use of automated and robotic scaffolding solutions. As the UAE continues to push the boundaries of construction, the integration of these advanced systems has become crucial for enhancing productivity, ensuring safety, and maintaining compliance with local regulations.

Sher Ahmed Scaffolding, a leading provider of scaffolding services in the UAE, has been at the forefront of this technological shift. By embracing automation and robotics, the company has been able to streamline its operations, reduce labor-intensive tasks, and provide its clients with a level of precision and efficiency that was unimaginable just a decade ago.

Regulatory Compliance and Safety Standards

One of the key drivers behind the adoption of automated and robotic scaffolding solutions in the UAE is the stringent regulatory environment. The UAE’s construction industry is subject to a comprehensive set of building codes and safety standards, designed to protect workers, ensure structural integrity, and minimize the risk of accidents.

The Abu Dhabi International Building Code (ADIBC) and the Dubai Municipality Building Code (DMBC) are two of the most influential regulatory frameworks in the region, outlining detailed requirements for the design, installation, and maintenance of scaffolding systems. These regulations mandate the use of specific safety equipment, load-bearing capacities, and inspection procedures, all of which can be more effectively managed through the integration of automated and robotic technologies.

Recent studies have shown that the implementation of advanced scaffolding solutions, such as automated platforms and robotic assembly, has led to a significant reduction in the number of safety incidents on construction sites. By minimizing the need for manual labor in high-risk areas, these technologies have helped to create a safer working environment, reducing the risk of falls, injuries, and other construction-related accidents.

Cost Optimization and Productivity Gains

In addition to the safety and regulatory benefits, the adoption of automated and robotic scaffolding solutions has also played a crucial role in optimizing costs and enhancing productivity in the UAE’s construction industry.

Reduced Labor Costs: One of the primary advantages of using automated and robotic scaffolding systems is the reduction in labor requirements. These advanced solutions can perform many tasks, such as assembly, disassembly, and material handling, with minimal human intervention, leading to significant cost savings. According to industry estimates, the use of automated scaffolding can result in labor cost reductions of up to 30% when compared to traditional manual methods.

Improved Efficiency and Productivity: Robotic and automated scaffolding systems are designed to operate with a high degree of precision and speed, outpacing traditional manual methods. This increased efficiency translates into faster project completion times, reduced downtime, and a more streamlined construction process. In some cases, the implementation of these technologies has resulted in productivity gains of up to 20% on construction sites.

Optimized Material Utilization: Automated and robotic scaffolding systems are often equipped with advanced sensors and software that can optimize the use of materials, minimizing waste and reducing overall project costs. By precisely cutting and assembling the required components, these systems can minimize material overages and ensure that every piece is utilized effectively.

Innovative Scaffolding Techniques

As the UAE’s construction industry continues to evolve, the use of automated and robotic scaffolding solutions has also given rise to a range of innovative techniques and practices. These advancements not only enhance productivity and safety but also introduce new possibilities for more complex and ambitious building projects.

Modular Scaffolding Systems: One of the notable trends in the UAE’s scaffolding industry is the increasing adoption of modular systems. These pre-engineered, standardized components can be quickly and efficiently assembled, reducing installation time and minimizing the need for manual labor. Modular scaffolding systems also offer greater flexibility, allowing for easy reconfiguration and adaptability to different project requirements.

Automated Climbing Systems: Another innovative technology gaining traction in the UAE is the use of automated climbing scaffolding systems. These platforms can self-propel vertically, following the progress of the construction work, without the need for manual relocation. This feature not only enhances productivity but also improves worker safety by eliminating the risks associated with manual climbing and dismantling.

Robotic Inspection and Maintenance: To ensure the ongoing safety and structural integrity of scaffolding systems, regular inspections and maintenance are essential. Robotic technologies have now been integrated into this process, allowing for more thorough and frequent inspections, as well as automated condition monitoring and preventive maintenance. This approach helps to identify and address potential issues before they can escalate, reducing downtime and the risk of accidents.

Cost Considerations and Estimates

The adoption of automated and robotic scaffolding solutions in the UAE comes with a range of cost considerations, both in terms of initial investments and long-term operational expenses.

Initial Investment: The implementation of these advanced technologies typically requires a higher upfront investment compared to traditional manual scaffolding systems. The cost of purchasing and integrating automated and robotic equipment can range from $50,000 to $150,000 per project, depending on the complexity and scale of the system.

Operational Costs: While the initial investment may be higher, the long-term operational costs associated with automated and robotic scaffolding can be significantly lower. Factors such as reduced labor requirements, improved material utilization, and decreased maintenance and downtime can lead to substantial cost savings over the lifetime of the project. Industry estimates suggest that the use of these technologies can result in operational cost reductions of up to 20% when compared to conventional scaffolding methods.

Return on Investment: The significant productivity gains and cost savings offered by automated and robotic scaffolding solutions often justify the higher upfront investment. Many construction companies in the UAE have reported a return on investment (ROI) within 12 to 24 months of implementing these technologies, making them a highly attractive option for enhancing profitability and competitiveness.

The Future of Scaffolding in the UAE

As the UAE continues to push the boundaries of construction excellence, the integration of automated and robotic scaffolding solutions will undoubtedly play an increasingly crucial role. These advanced technologies not only enhance productivity and safety but also ensure compliance with the region’s strict regulatory frameworks, ultimately contributing to the success and sustainability of the construction industry.

Sher Ahmed Scaffolding and other leading providers in the UAE have recognized the transformative potential of these innovations, investing heavily in the latest scaffolding technologies to deliver unparalleled services to their clients. By embracing this digital revolution, the UAE’s construction industry is poised to reach new heights of efficiency, safety, and cost-effectiveness, solidifying its position as a global leader in the built environment.