Navigating the Regulatory Landscape of Scaffolding in the UAE

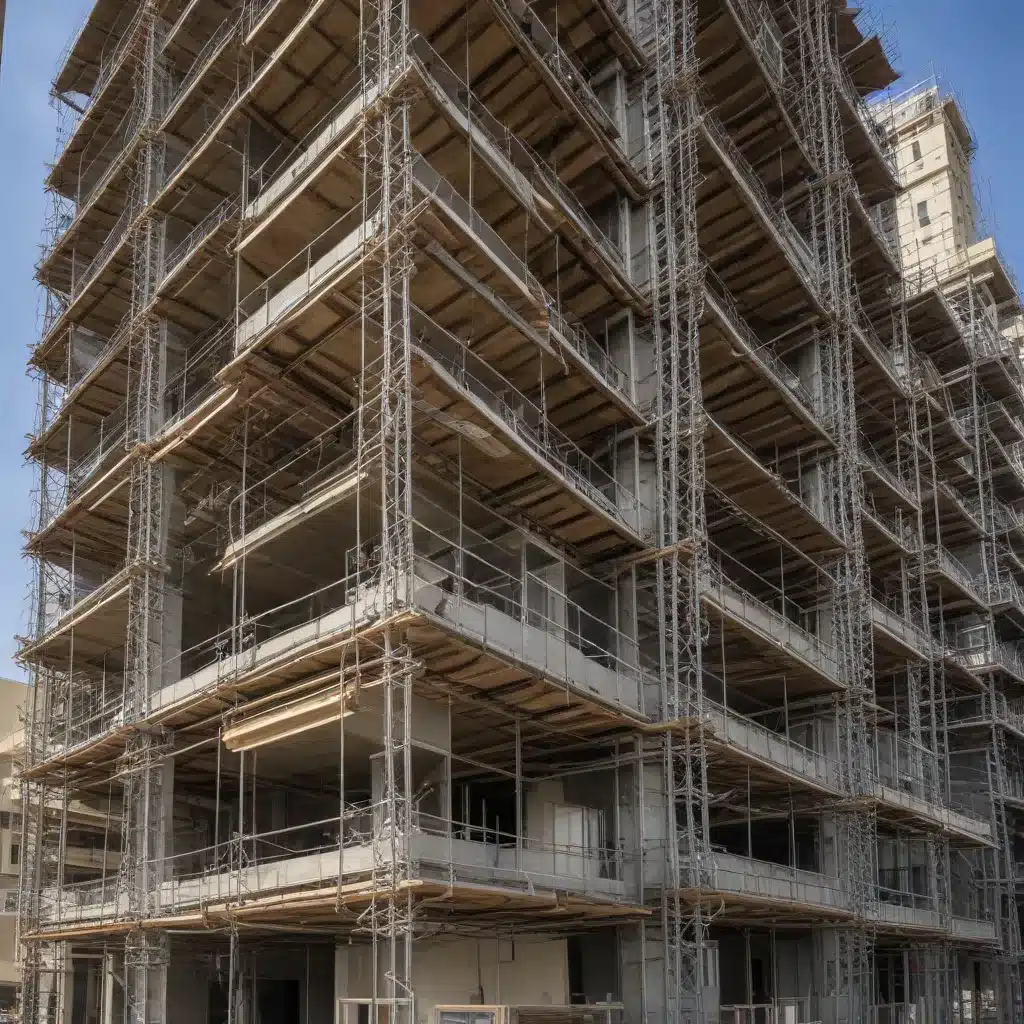

The construction industry in the United Arab Emirates (UAE) has experienced rapid growth in recent years, driven by ambitious infrastructure projects and the ever-evolving architectural landscape. As the country continues to shape its built environment, the role of scaffolding has become increasingly crucial, ensuring the safety and efficiency of construction sites. In this comprehensive article, we will explore the regulatory framework governing scaffolding in the UAE, highlighting the latest best practices and cost considerations for construction professionals.

One of the primary governing bodies overseeing scaffolding regulations in the UAE is the Occupational Safety and Health Administration (OSHA). The OSHA guidelines outline detailed requirements for the design, installation, and maintenance of scaffolding systems, emphasizing the importance of worker safety and structural integrity. These regulations cover a wide range of aspects, from the load-bearing capacity of the scaffolding to the appropriate use of safety harnesses and fall protection measures.

As per the OSHA regulations, all scaffolding in the UAE must be designed and erected by qualified personnel, with a focus on compliance with recognized engineering standards. Specifically, the UAE has adopted the British Standard BS EN 12811-1:2003, which sets forth comprehensive guidelines for the selection, design, and installation of temporary works, including scaffolding.

To ensure compliance, construction companies must obtain the necessary permits and approvals from local authorities before commencing any scaffolding-related work. This process typically involves submitting detailed engineering drawings, structural calculations, and a comprehensive safety plan for the scaffolding system. The local municipalities, such as the Dubai Municipality and the Abu Dhabi Urban Planning Council, play a crucial role in reviewing and approving these submissions, ensuring that the proposed scaffolding solutions meet all the required safety and performance standards.

Cost Considerations and Budgeting for Scaffolding in the UAE

The cost of scaffolding in the UAE can vary significantly depending on factors such as the size and complexity of the construction project, the materials used, and the duration of the scaffolding’s deployment. According to recent industry data, the average cost of scaffolding in the UAE ranges from $10 to $25 per square meter per month, with the higher end of the range typically associated with more advanced and specialized scaffolding systems.

| Scaffolding Type | Cost Range (USD/sq.m/month) |

|---|---|

| Basic Tube and Coupler Scaffolding | $10 – $15 |

| Modular Frame Scaffolding | $12 – $18 |

| System Scaffolding (e.g., Cuplock, Ringlock) | $15 – $25 |

It’s important to note that these cost estimates are based on the prevailing market rates in the UAE as of September 2024 and may be subject to fluctuations due to factors such as material availability, labor costs, and economic conditions.

To effectively manage scaffolding costs, construction companies in the UAE often explore various strategies, such as:

-

Optimizing Scaffolding Configuration: By carefully planning the layout and design of the scaffolding system, construction firms can minimize material usage and labor requirements, leading to significant cost savings.

-

Utilizing Modular or System Scaffolding: Advanced scaffolding solutions, such as modular frame or system scaffolding (e.g., Cuplock, Ringlock), often offer higher efficiency and reusability, which can translate to lower long-term costs compared to traditional tube-and-coupler systems.

-

Exploring Innovative Materials: The use of sustainable and lightweight materials, such as bamboo or recycled steel, can reduce the overall weight of the scaffolding, potentially lowering transportation and installation costs.

-

Implementing Effective Maintenance and Inspection Protocols: Proactive maintenance and regular inspections of the scaffolding can extend its lifespan, minimizing the need for frequent replacements or repairs, which can be a significant cost driver.

-

Leveraging Scaffolding Rental Services: Many construction companies in the UAE opt to rent scaffolding instead of purchasing it outright, allowing them to access the latest technologies and avoid the upfront capital investment required for ownership.

By thoroughly understanding the cost implications and actively managing scaffolding expenses, construction firms in the UAE can optimize their project budgets and enhance their overall profitability.

Innovative Scaffolding Solutions for the UAE’s Construction Industry

As the UAE’s construction industry continues to evolve, the demand for innovative and sustainable scaffolding solutions has grown exponentially. Recognizing the importance of enhancing safety, efficiency, and environmental responsibility, construction professionals in the region are actively exploring and implementing cutting-edge scaffolding technologies.

One such innovation that has gained traction in the UAE is the use of bamboo scaffolding. Bamboo, a fast-growing and renewable grass, offers several advantages over traditional metal or wooden scaffolding. Its high tensile strength, comparable to that of steel, makes it an excellent load-bearing material, while its lightweight nature can contribute to reduced transportation and installation costs. Furthermore, bamboo scaffolding is inherently eco-friendly, aligning with the UAE’s sustainability objectives and reducing the industry’s carbon footprint.

According to a recent study conducted by the American University of Sharjah, the use of bamboo scaffolding in construction projects in the UAE has demonstrated a cost savings of up to 20% compared to traditional metal scaffolding systems. Additionally, the study found that bamboo scaffolding can be installed up to 30% faster, leading to improved project timelines and overall efficiency.

Another innovative solution gaining traction in the UAE’s construction industry is the use of self-erecting scaffolding systems. These advanced systems, often operated by remote control or automated mechanisms, can significantly reduce the need for manual labor and improve worker safety by minimizing the exposure to height-related risks. Self-erecting scaffolding also offers the advantage of faster installation and dismantling, which can contribute to streamlined construction timelines and reduced project costs.

The UAE’s commitment to sustainable building practices has also paved the way for the adoption of modular and prefabricated scaffolding systems. These solutions, often made from recycled or sustainable materials, are designed for easy assembly and disassembly, reducing construction waste and minimizing the environmental impact of scaffolding installations. Additionally, the standardized nature of modular scaffolding allows for faster setup and more efficient utilization of materials, ultimately enhancing project productivity and cost-effectiveness.

Ensuring Scaffolding Safety in the UAE’s Construction Industry

Maintaining a safe and accident-free construction environment is a top priority in the UAE, and the regulations surrounding scaffolding play a crucial role in this endeavor. Construction companies in the UAE must adhere to stringent safety standards and best practices to protect their workers and ensure compliance with the local authorities.

One of the key safety requirements for scaffolding in the UAE is the mandatory use of personal protective equipment (PPE). This includes the provision of safety harnesses, hard hats, and other specialized equipment to mitigate the risks associated with working at heights. Employers are responsible for ensuring that all workers on the scaffolding have access to the appropriate PPE and are trained in its proper use.

The UAE’s OSHA regulations mandate that all scaffolding taller than 2 meters must be equipped with guardrails, mid-rails, and toe boards to prevent falls and protect workers from falling objects. Additionally, the scaffolding must be inspected daily by a competent person before use, and any necessary repairs or modifications must be addressed immediately.

Another crucial aspect of scaffolding safety in the UAE is the proper training and certification of workers. All personnel involved in the assembly, dismantling, and use of scaffolding must undergo comprehensive training programs that cover topics such as load-bearing capacities, safe work practices, and emergency response procedures. Construction companies must maintain detailed records of worker training and competency assessments to demonstrate compliance with the OSHA regulations.

To further enhance safety measures, the UAE has also prioritized the integration of advanced technologies into scaffolding systems. This includes the use of sensor-based monitoring systems that can automatically detect and alert workers to potential hazards, such as overloading or structural instability. Additionally, the adoption of Building Information Modeling (BIM) in the design and planning of scaffolding can help identify and mitigate safety risks before construction even begins.

By adhering to the UAE’s robust scaffolding safety regulations, construction companies can not only protect their workers but also demonstrate their commitment to responsible and sustainable building practices. This, in turn, can lead to enhanced project outcomes, improved industry reputation, and better long-term cost management through the prevention of accidents and associated liabilities.

Embracing Sustainability: Eco-Friendly Scaffolding Practices in the UAE

As the UAE continues to position itself as a global leader in sustainable development, the construction industry has also embraced the challenge of reducing its environmental impact. This shift has extended to the realm of scaffolding, where construction professionals are exploring innovative solutions to minimize waste, conserve resources, and contribute to a more eco-friendly built environment.

One of the prominent sustainable practices gaining traction in the UAE is the use of recycled steel for scaffolding. The steel industry has made significant strides in reducing its carbon footprint through the adoption of advanced production techniques, such as the use of electric arc furnaces powered by renewable energy sources. By incorporating recycled steel into their scaffolding systems, construction companies can not only conserve natural resources but also contribute to the circular economy by diverting waste from landfills.

According to a recent study by the Emirates Green Building Council, the use of recycled steel in scaffolding can result in a 40% reduction in the carbon footprint compared to traditional steel scaffolding. Furthermore, the recycling process requires up to 75% less energy than producing new steel from raw materials.

Another sustainable option gaining ground in the UAE is the integration of modular and prefabricated scaffolding systems. These solutions, often made from eco-friendly materials like bamboo or recycled plastics, are designed for easy assembly, disassembly, and reuse, minimizing construction waste and resource consumption. The modular nature of these systems also allows for more efficient material utilization, further enhancing their sustainability credentials.

To support the adoption of sustainable scaffolding practices, the UAE government has introduced various incentives and regulations. For instance, the Dubai Municipality has implemented a waste management program that encourages the recycling of construction materials, including scaffolding components. By providing financial incentives and streamlining the recycling process, the municipality aims to divert a significant portion of construction waste from landfills, aligning with the country’s broader sustainability objectives.

Furthermore, the UAE’s Green Building Regulations have also played a pivotal role in driving the adoption of eco-friendly scaffolding solutions. These regulations mandate the use of sustainable materials and practices in construction projects, including the selection and deployment of scaffolding systems. As a result, construction companies in the UAE are actively seeking out innovative and sustainable scaffolding options to meet these regulatory requirements and enhance their environmental credentials.

By embracing sustainable scaffolding practices, the UAE’s construction industry is not only contributing to environmental preservation but also positioning itself as a global leader in the adoption of innovative, cost-effective, and eco-friendly building solutions.

Conclusion

The UAE’s construction industry has embraced the integration of innovative scaffolding solutions, driven by a robust regulatory framework, cost-effective strategies, and a commitment to sustainability. By navigating the intricate scaffolding landscape, construction professionals in the region are leveraging advanced technologies, sustainable materials, and best safety practices to enhance project efficiency, worker safety, and environmental responsibility.

As the UAE continues to shape its built environment, the role of scaffolding will remain crucial in supporting the country’s ambitious development goals. By staying informed about the latest regulatory updates, cost-management techniques, and innovative scaffolding solutions, construction companies in the UAE can position themselves for success and contribute to the creation of a more sustainable, resilient, and thriving built environment.

To learn more about scaffolding services and construction safety in the UAE, explore the resources and expertise offered by leading providers in the region.