Regulatory Compliance and Best Practices for Scaffolding Safety in the UAE

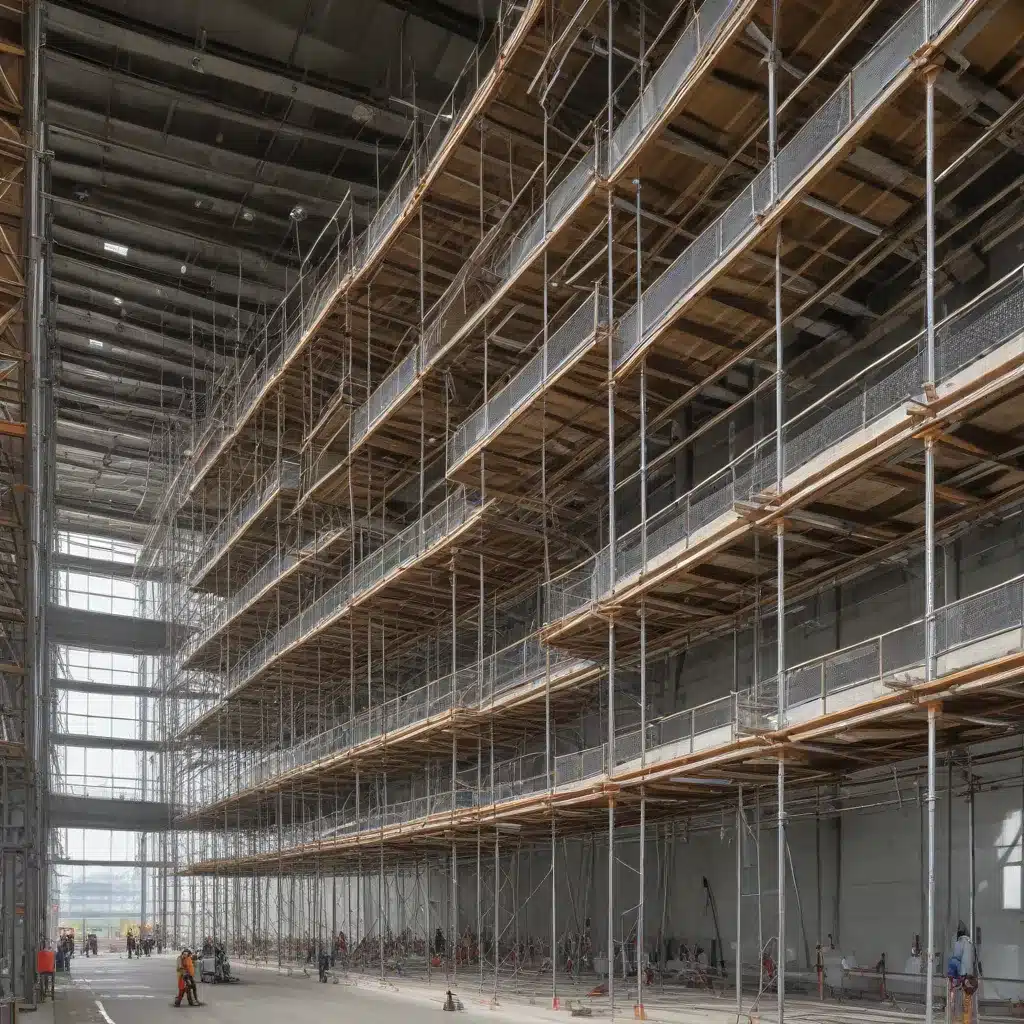

In the rapidly evolving construction landscape of the United Arab Emirates (UAE), ensuring the safety and reliability of scaffolding systems is of paramount importance. The UAE’s commitment to upholding the highest standards of construction practices is reflected in its comprehensive regulatory framework, which governs the selection, installation, and maintenance of scaffolding structures across diverse building projects.

UAE construction regulations mandate that all scaffolding installations adhere to stringent safety protocols, with a particular emphasis on weight capacity, weather resistance, and ongoing inspection procedures. These regulations are designed to protect workers, site supervisors, and the general public from the risks associated with improperly installed or maintained scaffolding structures.

Navigating the UAE’s Scaffolding Regulations

The UAE’s regulatory bodies, such as the Dubai Civil Defence and the Ministry of Human Resources and Emiratisation, have established comprehensive guidelines for scaffolding safety. These guidelines cover various aspects, including:

-

Material Selection: The regulations specify the use of high-quality steel or aluminum scaffolding, with a focus on ensuring structural integrity and load-bearing capacity. Steel scaffolding is preferred for large-scale, high-rise projects due to its exceptional strength and durability, while aluminum scaffolding is often utilized for smaller-scale tasks or in areas requiring frequent movement and setup.

-

Installation and Dismantling Protocols: Detailed procedures for the proper installation, bracing, and dismantling of scaffolding structures are mandated to minimize the risks of accidents or structural failures. Site supervisors are responsible for overseeing the entire process, ensuring strict adherence to safety guidelines.

-

Periodic Inspections: Regular inspections by certified professionals are required to assess the condition of scaffolding structures and identify any potential weaknesses or deterioration. These inspections are crucial in maintaining the integrity and safety of the systems, particularly in the face of harsh environmental conditions prevalent in the UAE.

-

Worker Training and Certifications: Construction companies are obligated to provide comprehensive training to their workers on the safe operation, handling, and maintenance of scaffolding systems. Workers must also possess the necessary certifications and qualifications to operate and work on scaffolding platforms.

-

Safety Equipment and Personal Protective Gear: The regulations mandate the use of appropriate safety equipment, such as harnesses, guardrails, and personal protective gear, to safeguard workers at heights and minimize the risk of falls or other scaffold-related accidents.

By adhering to these comprehensive regulations, construction companies in the UAE can ensure the safety and reliability of their scaffolding systems, while also demonstrating their commitment to the well-being of their workforce and the surrounding community.

Innovative Scaffolding Solutions for Diverse Construction Environments

The construction industry in the UAE is renowned for its ambitious and diverse projects, ranging from towering skyscrapers to intricate infrastructure developments. To meet the unique challenges posed by these varied construction environments, the industry has embraced innovative scaffolding solutions that combine advanced design, material selection, and deployment strategies.

Steel Scaffolding for High-Rise and Heavy-Duty Projects

Steel scaffolding has emerged as the preferred choice for large-scale, high-rise construction projects in the UAE due to its exceptional strength, stability, and load-bearing capacity. These attributes make steel scaffolding an ideal solution for supporting the weight of heavy construction materials, equipment, and a large workforce at considerable heights.

One notable example is the construction of the iconic Burj Khalifa, the world’s tallest skyscraper, which utilized extensive steel scaffolding throughout the project. The scaffolding’s structural integrity and weight-bearing capabilities enabled workers to navigate the building’s extraordinary heights safely, contributing to the successful completion of this architectural marvel.

Similarly, the construction of major infrastructure projects, such as bridges and stadiums, often relies on the use of steel scaffolding. The robust nature of steel scaffolding ensures that these structures can withstand the demands of heavy machinery, materials, and the rigors of construction, all while providing a secure working environment for the workforce.

Aluminum Scaffolding for Maintenance and Accessibility

While steel scaffolding excels in large-scale, high-intensity construction projects, aluminum scaffolding has emerged as a versatile solution for maintenance, renovation, and accessibility-focused tasks in the UAE. Owing to its lightweight and corrosion-resistant properties, aluminum scaffolding is particularly well-suited for applications that require frequent relocation or exposure to harsh environmental conditions.

The restoration and maintenance of historical landmarks, such as the Bastakiya Quarter in Dubai, often utilize aluminum scaffolding. This lightweight and maneuverable scaffolding system allows workers to safely access and maintain the intricate architectural details of these heritage sites without causing damage to the delicate structures.

Similarly, the refurbishment of coastal structures, like lighthouses, frequently employs aluminum scaffolding due to its inherent resistance to corrosion from salty air and harsh weather conditions. This ensures the safety and longevity of the scaffolding system, even in the face of challenging environmental factors.

Adapting Scaffolding Solutions to Unique Construction Challenges

The construction landscape in the UAE is marked by diverse challenges, ranging from dense urban environments to remote locations with limited accessibility. Contractors and scaffolding providers must carefully assess the unique requirements of each project to determine the most appropriate scaffolding solution.

For example, the renovation of a shopping mall in a bustling metropolitan area may call for a modular, easily maneuverable aluminum scaffolding system that can be quickly assembled and dismantled without disrupting the ongoing operations of the facility. Conversely, the construction of a new residential complex in a remote desert location may necessitate the use of sturdy, weather-resistant steel scaffolding that can withstand the region’s harsh environmental conditions.

By staying attuned to the specific requirements of each construction project, scaffolding providers in the UAE can offer tailored solutions that enhance safety, efficiency, and cost-effectiveness, ultimately contributing to the successful completion of these diverse building endeavors.

Cost Considerations and Long-Term Savings

The selection of the right scaffolding solution for a construction project in the UAE involves a careful evaluation of both upfront costs and long-term cost savings. While the initial investment in scaffolding may vary between different materials and systems, the focus on cost-effective and sustainable practices has become increasingly important in the Emirates’ construction industry.

Comparing Upfront Costs of Steel and Aluminum Scaffolding

Steel scaffolding typically presents a lower upfront cost compared to aluminum scaffolding due to its broader availability and established manufacturing processes. On average, the cost of steel scaffolding in the UAE ranges from $8 to $12 per square meter, depending on the project’s scale and specific requirements.

Aluminum scaffolding, on the other hand, generally has a higher initial cost, with prices ranging from $12 to $18 per square meter in the UAE. This premium is primarily attributed to the more specialized manufacturing processes and the inherent properties of aluminum, which provide enhanced portability and corrosion resistance.

Evaluating Long-Term Cost Savings

While the upfront cost of steel scaffolding may be lower, its long-term cost-effectiveness often outweighs the initial investment. Steel scaffolding’s exceptional durability and longevity result in reduced maintenance expenses over the course of a project. Additionally, the structural integrity of steel scaffolding minimizes the risk of accidents and project delays, further contributing to cost savings.

Conversely, the higher initial cost of aluminum scaffolding is often offset by its reduced maintenance requirements and increased adaptability. Aluminum’s inherent resistance to corrosion means that periodic inspections and repairs are less frequent, leading to long-term cost savings for construction companies.

Balancing Upfront Costs and Long-Term Savings

When selecting the appropriate scaffolding solution for a construction project in the UAE, construction managers and project stakeholders must carefully weigh the upfront costs against the potential long-term savings. Factors such as the project’s duration, environmental conditions, and specific safety requirements should all be taken into consideration.

For large-scale, high-intensity construction projects with an extended timeline, the superior durability and load-bearing capacity of steel scaffolding may prove to be the more cost-effective choice, despite the higher initial investment. Conversely, for shorter-term projects or those requiring frequent relocation, the lower maintenance needs and enhanced portability of aluminum scaffolding may be the more economical solution.

By striking the right balance between upfront costs and long-term cost savings, construction companies in the UAE can optimize their scaffolding investments, ensuring the successful completion of their projects while adhering to the highest safety standards.

Conclusion

The construction industry in the UAE has embraced a comprehensive regulatory framework and innovative scaffolding solutions to ensure the safety and reliability of its building projects. By adhering to stringent guidelines, construction companies in the Emirates can leverage the unique strengths of steel and aluminum scaffolding to address the diverse challenges posed by their construction environments.

As the UAE continues to push the boundaries of architectural and engineering feats, the role of advanced scaffolding systems will only become more crucial. By striking the right balance between upfront costs and long-term savings, construction professionals can optimize their scaffolding investments, ultimately contributing to the successful and safe completion of their projects.

By staying at the forefront of scaffolding innovations and maintaining a steadfast commitment to regulatory compliance, the construction industry in the UAE is well-positioned to navigate the challenges of the modern built environment, ushering in a new era of sustainable and safe construction practices.