Embracing the Evolution of Scaffolding Practices

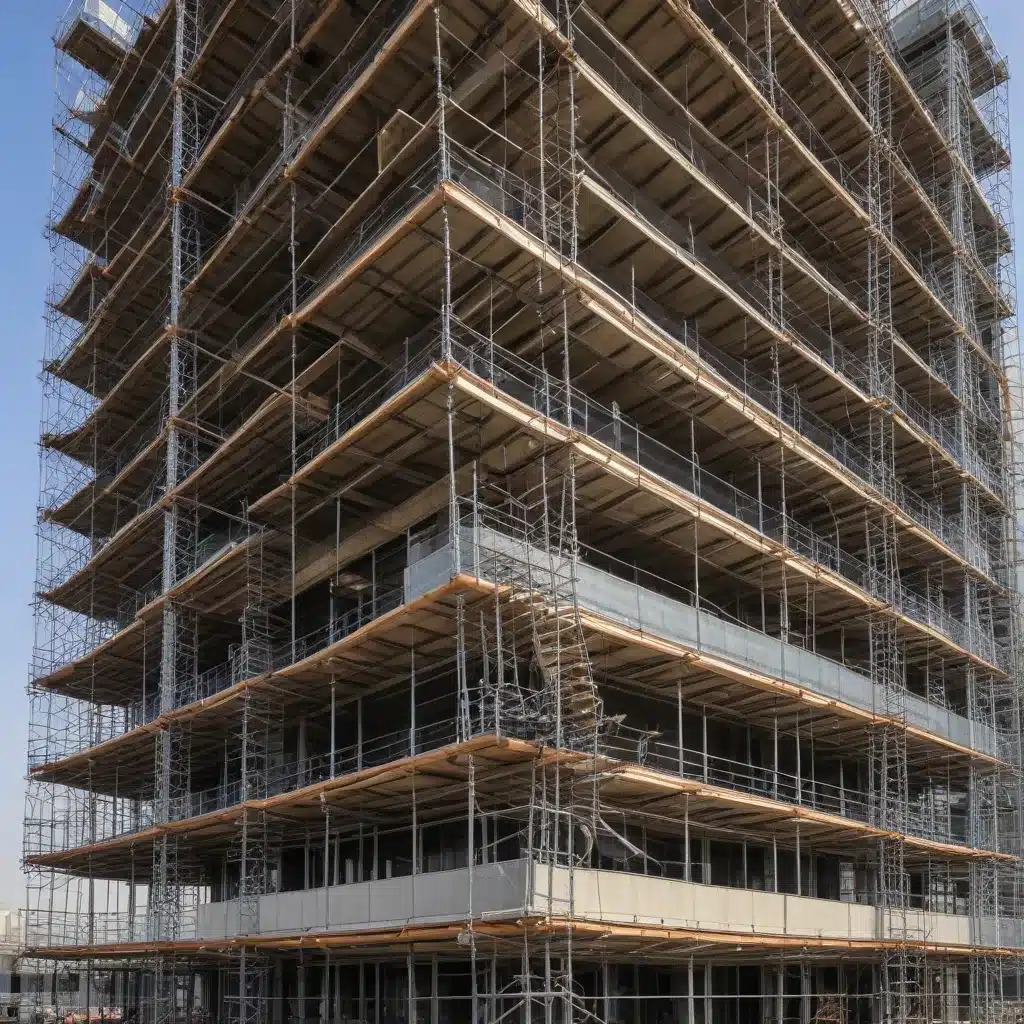

The construction industry in the United Arab Emirates (UAE) has witnessed remarkable advancements in recent years, driven by a commitment to safety, efficiency, and sustainability. At the heart of this transformation lies the evolution of scaffolding practices, which have become integral to ensuring the successful completion of complex building projects while prioritizing worker well-being and regulatory compliance.

As the UAE continues to emerge as a global leader in construction, the demand for innovative scaffolding solutions has grown exponentially. Contractors and project managers are now exploring cutting-edge technologies, materials, and techniques to streamline their operations, reduce costs, and enhance overall safety standards. This article delves into the latest developments in the UAE’s scaffolding landscape, highlighting the regulatory frameworks, cost-effective strategies, and best practices that are shaping the future of construction in the region.

Navigating the Regulatory Landscape: Scaffolding Standards in the UAE

The UAE’s commitment to safety is reflected in its robust set of regulations and guidelines governing the use of scaffolding on construction sites. The UAE Construction Safety Code outlines detailed requirements for the design, installation, and maintenance of scaffolding systems, ensuring that they meet the highest safety standards.

One of the key regulations stipulates that all scaffolding structures must be designed and certified by a licensed professional engineer, who is responsible for ensuring the structural integrity and compliance with local building codes. Additionally, regular inspections by qualified personnel are mandatory to identify and address any potential safety hazards.

The UAE’s safety regulations also emphasize the importance of comprehensive training for workers involved in the installation, dismantling, and use of scaffolding. Specialized courses and certifications are required to ensure that employees possess the necessary skills and knowledge to handle scaffolding safely, reducing the risk of accidents and injuries on the job site.

Compliance with these regulations is not only a legal requirement but also a critical factor in maintaining the trust and confidence of clients, project stakeholders, and the broader construction community. Contractors who prioritize adherence to these standards are often favored for their commitment to worker safety and their ability to deliver projects on time and within budget.

Optimizing Scaffolding Costs: Strategies for Effective Cost Management

The construction industry in the UAE is highly competitive, with contractors continuously seeking ways to optimize their operational costs and maintain a competitive edge. When it comes to scaffolding, the ability to manage expenses effectively can have a significant impact on a project’s overall profitability.

One of the key strategies employed by construction firms in the UAE is the utilization of modular and prefabricated scaffolding systems. These innovative solutions, which can be easily assembled and disassembled, offer several advantages over traditional scaffolding methods. They often require less labor, reduce material waste, and can be reused across multiple projects, thereby lowering the overall cost per project.

Additionally, the UAE’s construction industry has witnessed a growing trend towards the use of aluminum scaffolding systems. Compared to traditional steel scaffolding, aluminum is lighter, more durable, and less susceptible to corrosion, making it a cost-effective choice for many construction projects. The reduced weight of aluminum scaffolding also translates into lower transportation and installation costs, further enhancing the overall savings.

Another area of cost optimization is the implementation of advanced planning and project management techniques. By carefully mapping out the scaffolding requirements and coordinating the delivery of materials, construction firms can minimize downtime, reduce material waste, and optimize the use of their scaffolding assets across multiple projects.

To illustrate the impact of these cost-saving strategies, consider the following comparison:

| Scaffolding Technique | Average Cost per Square Meter (USD) |

|---|---|

| Traditional Steel Scaffolding | $25 – $35 |

| Modular/Prefabricated Scaffolding | $18 – $25 |

| Aluminum Scaffolding | $20 – $30 |

As this table demonstrates, the adoption of innovative scaffolding solutions can result in significant cost savings, ultimately improving the bottom line for construction companies operating in the UAE.

Embracing Technological Advancements: The Future of Scaffolding in the UAE

The construction industry in the UAE is at the forefront of technological innovation, and the scaffolding sector is no exception. Contractors and scaffolding providers are continuously exploring and implementing cutting-edge technologies to enhance safety, efficiency, and overall project delivery.

One such advancement is the use of Building Information Modeling (BIM) in the design and planning of scaffolding systems. By integrating BIM into their workflows, construction firms can create detailed 3D models of the scaffolding structure, allowing for precise planning, clash detection, and optimization of material usage. This, in turn, leads to faster installation, reduced waste, and improved safety on the job site.

Another emerging trend is the adoption of drone technology for the inspection and monitoring of scaffolding structures. Drones equipped with high-resolution cameras and sensors can perform regular inspections, capturing detailed data on the condition of the scaffolding, potential issues, and any necessary maintenance requirements. This automated approach not only enhances safety but also reduces the need for manual inspections, saving time and resources.

Furthermore, the UAE’s construction industry has embraced the use of smart sensors and IoT (Internet of Things) devices to monitor the performance and safety of scaffolding systems. These sensors can provide real-time data on load-bearing capacity, structural integrity, and environmental factors, enabling construction teams to make informed decisions and proactively address any concerns.

As the UAE continues to push the boundaries of technological innovation, the scaffolding sector is poised to witness even more transformative advancements in the coming years. From the integration of augmented reality (AR) for improved visualization to the exploration of robotic systems for automated installation and dismantling, the future of scaffolding in the UAE is undoubtedly exciting and full of possibilities.

Prioritizing Safety: Best Practices for Scaffolding in the UAE

At the core of the UAE’s construction industry lies a steadfast commitment to worker safety, and the scaffolding sector is no exception. Construction firms operating in the UAE must adhere to a comprehensive set of safety guidelines and best practices to ensure the well-being of their employees and the overall success of their projects.

One of the most critical aspects of scaffolding safety is the proper selection and use of personal protective equipment (PPE). Workers involved in the installation, maintenance, and use of scaffolding are required to wear hard hats, safety harnesses, gloves, and other appropriate PPE to mitigate the risk of falls, struck-by incidents, and other potential hazards.

In addition to PPE, the UAE’s construction industry has also prioritized the use of advanced fall protection systems, such as guardrails, toe boards, and netting. These safety measures are not only mandatory but also play a crucial role in preventing workers from falling from height and minimizing the severity of any potential accidents.

Another important aspect of scaffolding safety is the comprehensive training and certification of workers. Construction firms in the UAE must ensure that their employees undergo specialized training programs that cover the proper installation, use, and dismantling of scaffolding systems. This training, coupled with regular safety refresher courses, helps to keep workers informed of the latest safety protocols and best practices.

To further enhance safety, the UAE’s construction industry has also embraced the use of innovative scaffolding designs and materials. For example, the adoption of modular and prefabricated scaffolding systems has not only improved cost-efficiency but also reduced the risk of human error during installation and dismantling.

By consistently adhering to these safety best practices, construction firms in the UAE are not only safeguarding their workers but also demonstrating their commitment to the overall well-being of the industry and the community at large.

Conclusion: Shaping the Future of Construction in the UAE

The scaffolding industry in the UAE has undergone a remarkable transformation, driven by a relentless pursuit of safety, efficiency, and innovation. Through the implementation of stringent regulatory frameworks, cost-effective strategies, and the embrace of technological advancements, construction firms in the UAE are redefining the standards for scaffolding practices and setting the stage for a more sustainable and prosperous future.

As the UAE continues to cement its position as a global leader in construction, the scaffolding sector will undoubtedly play a pivotal role in shaping the built environment of the region. By staying at the forefront of industry trends, prioritizing worker safety, and leveraging the power of emerging technologies, construction professionals in the UAE are poised to revolutionize the way scaffolding is designed, installed, and utilized, ultimately paving the way for a new era of construction excellence.