Navigating the Scaffolding Landscape: Compliance and Regulatory Frameworks

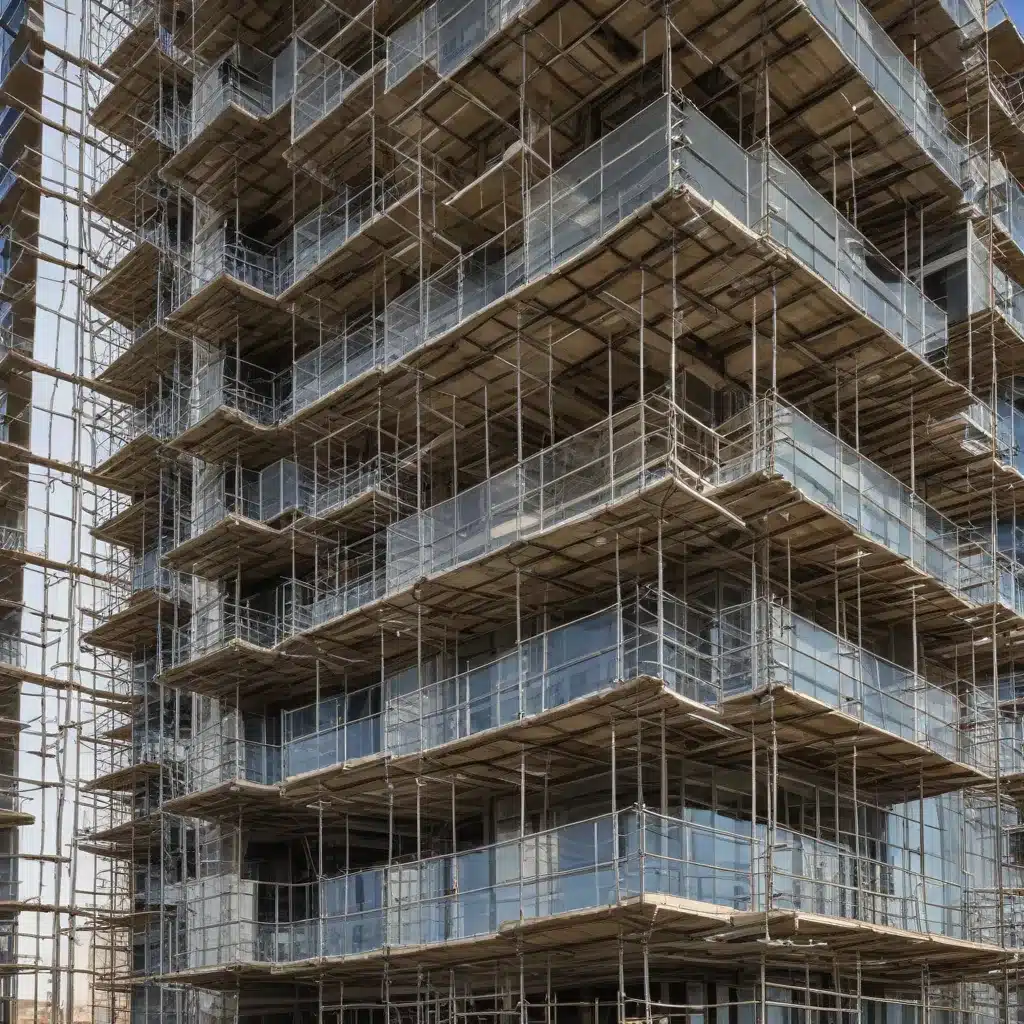

In the rapidly evolving construction industry of the United Arab Emirates (UAE), ensuring compliance with local regulations and industry best practices is paramount. As the region experiences a surge in large-scale projects and ambitious architectural feats, the role of scaffolding has become increasingly critical. Contractors and construction managers must navigate a complex web of safety standards, material specifications, and installation protocols to ensure the well-being of workers and the integrity of their projects.

The UAE’s scaffolding regulations are overseen by the Ministry of Human Resources and Emiratisation (MOHRE), which has established comprehensive guidelines to govern the use of temporary structures on construction sites. These regulations cover a wide range of aspects, including the selection of appropriate scaffolding materials, the qualifications and training of workers, and the implementation of robust fall protection systems. Compliance with MOHRE standards is not only a legal requirement but also a crucial factor in maintaining a safe and productive work environment.

Regulatory Compliance: Key Considerations

-

Material Specifications: The UAE’s scaffolding regulations stipulate the use of high-quality materials, such as steel, aluminum, or reinforced concrete, to ensure the structural integrity of the temporary structures. Contractors must carefully select and source components that meet the specified strength, durability, and corrosion-resistance requirements.

-

Worker Competency: Construction workers engaged in scaffolding activities must undergo comprehensive training and possess the necessary certifications to ensure they can safely assemble, inspect, and dismantle the temporary structures. The MOHRE mandates specific training programs and proficiency assessments to validate the competency of the workforce.

-

Fall Protection Systems: Robust fall protection measures, including guardrails, toe boards, and personal fall arrest systems, are mandatory on all scaffolding installations. Employers must provide workers with the appropriate personal protective equipment (PPE) and ensure its proper use to mitigate the risk of falls from height.

-

Inspection and Maintenance: Regular inspections and maintenance of scaffolding structures are critical to maintaining their structural integrity and safety. The MOHRE requires contractors to have a designated competent person responsible for conducting thorough inspections at specified intervals and documenting the findings.

-

Site-Specific Planning: Contractors must develop comprehensive site-specific plans that address the unique challenges and requirements of each construction project. These plans should outline the scaffolding design, installation procedures, and emergency response protocols to ensure compliance with the local regulations.

Innovative Scaffolding Solutions: Enhancing Safety and Efficiency

As the construction industry in the UAE continues to evolve, innovative scaffolding solutions are emerging that enhance safety, improve productivity, and reduce overall project costs. These advanced systems are transforming the way contractors approach temporary structures, offering a range of benefits that align with the region’s focus on sustainable and technologically advanced construction practices.

Modular Scaffolding Systems

One of the most prominent innovations in the UAE’s scaffolding landscape is the adoption of modular systems. These prefabricated, lightweight components can be quickly assembled and disassembled, reducing the time and labor required for installation. Modular scaffolding systems also offer greater flexibility, allowing for adaptable configurations to accommodate various project requirements and site constraints.

The cost-effectiveness of modular scaffolding is a significant advantage, as it can lead to significant savings on material procurement and labor expenses. Additionally, the modular design often incorporates enhanced safety features, such as integrated guardrails and toe boards, further contributing to a safer work environment.

Automated Scaffolding Solutions

Robotic and automated scaffolding solutions are gaining traction in the UAE, providing construction teams with a more efficient and technologically advanced approach to temporary structure installation and management. These systems utilize advanced sensors, control systems, and remote-controlled mechanisms to streamline the erection, adjustment, and dismantling of scaffolding, reducing the need for manual labor and minimizing the risk of human error.

Automated scaffolding solutions not only enhance productivity but also improve worker safety by minimizing their exposure to potential hazards during the installation process. These systems can be programmed to adhere to regulatory requirements, ensuring compliance with MOHRE standards while optimizing the overall construction workflow.

Modular and Automated Scaffolding Cost Comparison

To illustrate the cost implications of these innovative scaffolding solutions, consider the following comparison in United States Dollars (USD) for a typical 10-story building project in the UAE:

| Scaffolding Solution | Material Cost (USD) | Labor Cost (USD) | Total Cost (USD) |

|---|---|---|---|

| Traditional Scaffolding | $150,000 | $80,000 | $230,000 |

| Modular Scaffolding | $120,000 | $60,000 | $180,000 |

| Automated Scaffolding | $180,000 | $40,000 | $220,000 |

As the data suggests, the initial material cost for automated scaffolding may be higher, but the significant reduction in labor expenses can lead to overall cost savings compared to traditional methods. Modular scaffolding, on the other hand, provides a more balanced approach, offering a lower total cost while still delivering enhanced efficiency and safety benefits.

Embracing Sustainability: Eco-Friendly Scaffolding Practices

Alongside the pursuit of innovative scaffolding solutions, the construction industry in the UAE has also placed a strong emphasis on sustainable practices. As the region strives to reduce its environmental footprint and promote green development, contractors are increasingly exploring eco-friendly scaffolding options that minimize waste, conserve resources, and contribute to the broader sustainability goals.

Sustainable Material Selection

The UAE’s scaffolding regulations encourage the use of materials that are environmentally friendly and can be easily recycled or repurposed. This includes the utilization of aluminum, which is lightweight, corrosion-resistant, and can be recycled multiple times without losing its structural integrity. Additionally, the use of sustainable timber, such as certified hardwoods or bamboo, is gaining traction as a viable alternative to traditional steel or wooden scaffolding components.

Waste Reduction and Recycling

Responsible waste management is a crucial aspect of sustainable scaffolding practices in the UAE. Contractors are implementing comprehensive recycling programs to divert used scaffolding materials from landfills, minimizing the environmental impact. This includes the proper collection, sorting, and processing of components like metal, plastic, and wood, which can then be reintroduced into the supply chain or repurposed for other construction applications.

Rental and Reuse Initiatives

To further promote sustainability, some construction companies in the UAE are exploring scaffolding rental and reuse programs. These initiatives allow contractors to access high-quality temporary structures without the need for outright ownership, reducing the overall material consumption and waste associated with the construction lifecycle. By facilitating the sharing and reuse of scaffolding components, these programs contribute to a more circular economy and minimize the industry’s environmental footprint.

Integrating BIM and Digital Transformation

The construction industry in the UAE is embracing the power of digital transformation, and the scaffolding sector is no exception. Building Information Modeling (BIM) and other advanced technologies are revolutionizing the way contractors approach temporary structure planning, installation, and management, leading to enhanced collaboration, data-driven decision-making, and increased efficiency.

BIM-Enabled Scaffolding Design and Coordination

BIM software has become a valuable tool for construction professionals in the UAE, allowing them to virtually model and simulate the scaffolding requirements for a project. By integrating scaffolding data into the BIM model, contractors can identify potential conflicts, optimize the design, and ensure seamless coordination among various project stakeholders. This holistic approach to scaffolding planning enables more effective risk mitigation, improved site logistics, and better alignment with regulatory requirements.

Augmented Reality and Visualization

Augmented reality (AR) technology is also making inroads in the UAE’s scaffolding industry, providing construction teams with enhanced visualization capabilities. AR-enabled applications allow workers to overlay digital scaffolding models onto the actual construction site, enabling them to visualize the temporary structures in their intended locations. This improved spatial awareness can lead to more efficient installation, better adherence to safety protocols, and easier identification of potential issues before they arise.

Integrated Project Management and Collaboration

The integration of scaffolding data within comprehensive project management platforms is another key trend in the UAE’s construction industry. By seamlessly connecting scaffolding information with other project data, such as schedules, budgets, and safety records, contractors can streamline decision-making, enhance collaboration, and maintain greater control over the overall construction process. This holistic approach to project management can result in cost savings, improved productivity, and reduced risks throughout the project lifecycle.

Conclusion

As the construction industry in the UAE continues to evolve, the role of scaffolding has become increasingly crucial in the region’s ambitious development plans. Contractors and construction professionals must navigate a complex regulatory landscape while embracing innovative solutions to enhance safety, efficiency, and sustainability. By adhering to MOHRE’s scaffolding guidelines, leveraging advanced modular and automated systems, and integrating digital technologies, construction companies in the UAE can unlock a new era of productivity, cost management, and environmental stewardship.

At https://sherahmedscaffolding.com/, we are committed to supporting the UAE’s construction industry by providing cutting-edge scaffolding services and technical expertise. Our team of experts is well-versed in the latest regulatory requirements, innovative scaffolding practices, and sustainable construction methodologies. We invite you to explore our comprehensive solutions and discover how we can collaborate to transform your construction projects in the UAE.