Regulatory Compliance: Navigating the UAE’s Scaffolding Standards

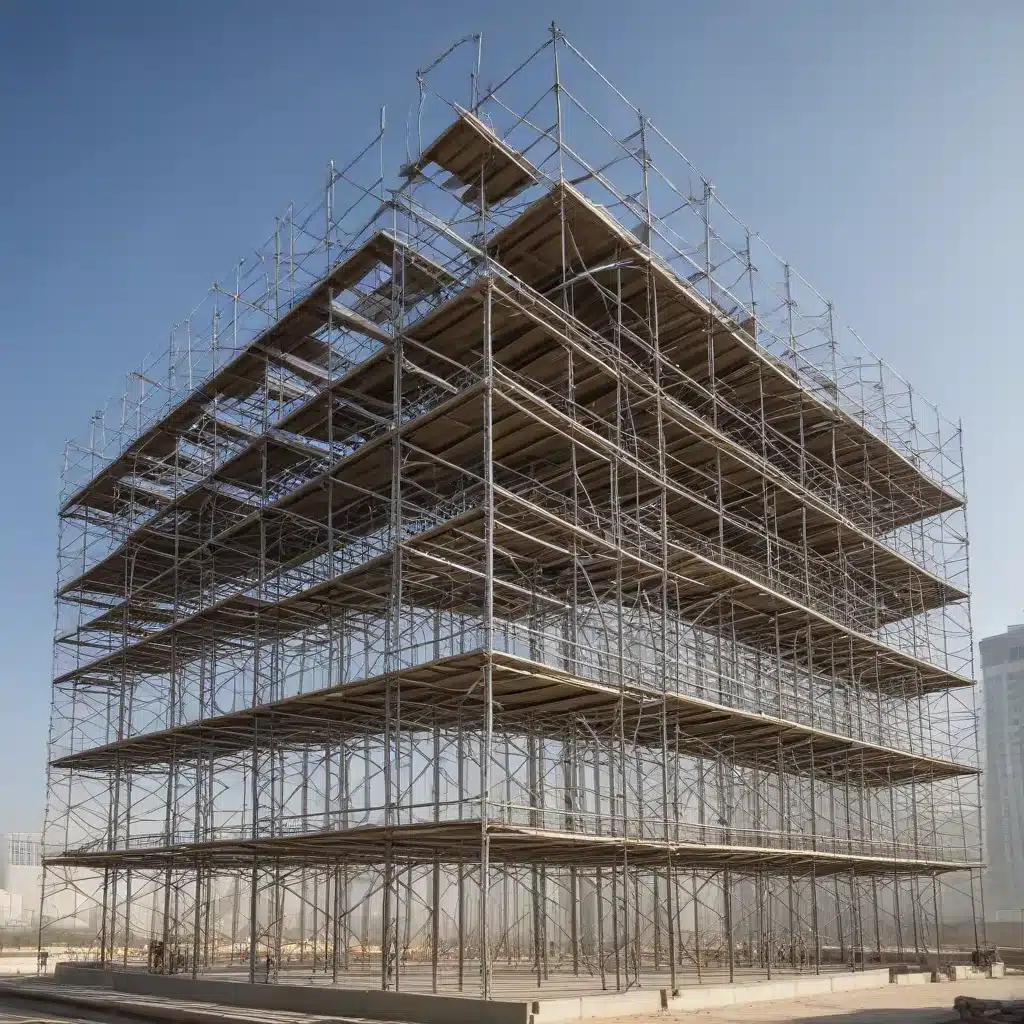

In the rapidly evolving construction landscape of the United Arab Emirates (UAE), the importance of adhering to stringent scaffolding regulations cannot be overstated. As a hub for ambitious infrastructure projects, the UAE has established a comprehensive set of guidelines and standards to ensure the safety and efficiency of scaffolding systems used on job sites.

The UAE’s scaffolding regulations are primarily governed by the Ministry of Human Resources and Emiratisation (MOHRE), which oversees the implementation and enforcement of these measures. These regulations cover a wide range of aspects, including the design, installation, inspection, and maintenance of scaffolding structures. Contractors and construction professionals must familiarize themselves with these guidelines to ensure compliance and mitigate the risk of non-compliance, which can result in hefty fines and project delays.

One of the key requirements outlined in the UAE’s scaffolding regulations is the mandatory use of certified, trained personnel for the erection, dismantling, and inspection of scaffolding systems. This includes the presence of a competent “scaffolding supervisor” on-site, responsible for overseeing the entire process and ensuring adherence to safety protocols. Additionally, all scaffolding components must be sourced from approved suppliers and must meet specific quality standards, as outlined in the regulations.

Regarding the design and installation of scaffolding, the UAE’s regulations emphasize the importance of thorough planning and engineering. Contractors must submit detailed scaffolding plans for review and approval by the relevant authorities before commencing construction. These plans must demonstrate compliance with load-bearing capacity requirements, appropriate bracing and anchoring systems, and the use of authorized access points, among other criteria.

Regular inspections and maintenance of scaffolding structures are also mandated by the UAE’s regulations. Scaffolding must undergo thorough inspections before each use, as well as periodic inspections by certified professionals. Any identified defects or non-conformities must be promptly addressed to maintain the structural integrity and safety of the scaffolding.

Staying up-to-date with the latest regulatory changes and industry best practices is crucial for construction companies operating in the UAE. Investing in training, quality equipment, and robust inspection protocols can not only ensure compliance but also enhance overall site safety and productivity.

Cost Management Strategies: Optimizing Scaffolding Expenditures

Alongside regulatory compliance, the efficient management of scaffolding-related costs is a crucial consideration for construction firms in the UAE. Scaffolding can account for a significant portion of a project’s overall budget, making it essential to adopt cost-effective strategies that maximize return on investment.

One effective approach to managing scaffolding costs is the implementation of modular or system-based scaffolding solutions. These advanced systems, which can be easily assembled and reconfigured, often prove more cost-effective than traditional, custom-built scaffolding. By reducing the need for extensive on-site fabrication and labor, modular systems can help construction firms save on material and labor costs, while also streamlining the installation and dismantling processes.

Another strategy for cost optimization is the careful planning and optimization of scaffolding usage throughout the project lifecycle. This involves conducting thorough site surveys, accurately estimating the required scaffolding quantities, and developing a detailed utilization plan. By minimizing the amount of scaffolding required and optimizing its deployment, construction firms can significantly reduce their overall expenditures.

The adoption of rental or leasing models for scaffolding equipment can also be a compelling cost-saving measure. Rather than investing in the outright purchase of scaffolding, construction firms can opt to rent the necessary components, thereby avoiding the upfront capital expenditure and the ongoing maintenance costs associated with ownership. This approach provides greater flexibility and the ability to scale scaffolding resources as project demands fluctuate.

Furthermore, construction firms can explore the potential of secondhand or refurbished scaffolding equipment, which can offer substantial cost savings compared to new purchases. While the condition and safety of these components must be carefully evaluated, a well-managed secondhand scaffolding program can contribute to significant cost reductions without compromising quality or safety.

Ultimately, the successful management of scaffolding costs in the UAE requires a multifaceted approach, combining the strategic deployment of advanced scaffolding systems, careful planning and utilization, and the exploration of alternative procurement models. By implementing these cost-optimization strategies, construction firms can enhance their overall project profitability and competitiveness in the UAE’s thriving construction market.

Innovative Scaffolding Practices: Enhancing Efficiency and Safety

As the construction industry in the UAE continues to evolve, the demand for innovative scaffolding solutions that enhance efficiency, safety, and sustainability has become increasingly pressing. Construction firms in the UAE are actively embracing new technologies and best practices to optimize their scaffolding operations and stay ahead of the curve.

One such innovation is the integration of digital tools and automation into the scaffolding process. The use of Building Information Modeling (BIM) software, for instance, allows construction teams to virtually plan, design, and simulate the installation of scaffolding systems, enabling them to identify potential challenges and optimize the layout before any physical work begins. This digital approach can lead to significant time and cost savings, as well as improved site safety by mitigating the risk of errors or congestion during the actual installation.

Another emerging trend in the UAE’s scaffolding landscape is the adoption of modular or system-based scaffolding solutions, as mentioned earlier. These advanced systems, which feature pre-engineered components and streamlined assembly processes, offer several advantages over traditional scaffolding. They can be erected and dismantled more efficiently, reducing the overall time and labor required on-site. Moreover, modular scaffolding systems often provide superior safety features, such as integrated fall protection and enhanced load-bearing capabilities, helping to safeguard workers and comply with the UAE’s stringent safety regulations.

The use of lightweight and innovative materials in scaffolding construction is also gaining traction in the UAE. Alternatives to traditional steel or wood, such as aluminum or composite materials, can offer significant weight reductions, improving both the ease of handling and the structural integrity of the scaffolding. These lightweight solutions can contribute to improved worker ergonomics, reduced wear and tear on equipment, and enhanced overall site mobility.

In addition to technical innovations, construction firms in the UAE are also embracing more sustainable and environmentally friendly scaffolding practices. This includes the adoption of reusable or recyclable scaffolding components, as well as the implementation of waste management protocols to minimize the environmental impact of scaffolding operations. By embracing these sustainable practices, construction companies can not only enhance their environmental credentials but also contribute to the UAE’s broader sustainability goals.

As the UAE continues to push the boundaries of innovation in the construction industry, the scaffolding sector is poised to play a pivotal role in driving efficiency, safety, and sustainability. By staying informed about the latest advancements, investing in cutting-edge technologies, and prioritizing best practices, construction firms in the UAE can position themselves as leaders in the evolving scaffolding landscape.

Conclusion

The UAE’s construction industry is a dynamic and rapidly evolving landscape, where the optimization of scaffolding systems is crucial for ensuring project success, worker safety, and overall efficiency. By navigating the complex web of regulatory requirements, implementing cost-effective strategies, and embracing innovative scaffolding practices, construction firms in the UAE can position themselves for long-term growth and competitiveness.

As the industry continues to evolve, Shera Med Scaffolding remains at the forefront of providing comprehensive scaffolding solutions that adhere to local regulations, maximize cost-efficiency, and leverage the latest technological advancements. By partnering with industry-leading experts and staying attuned to the changing landscape, construction firms in the UAE can unlock new levels of productivity, safety, and profitability in their scaffolding operations.