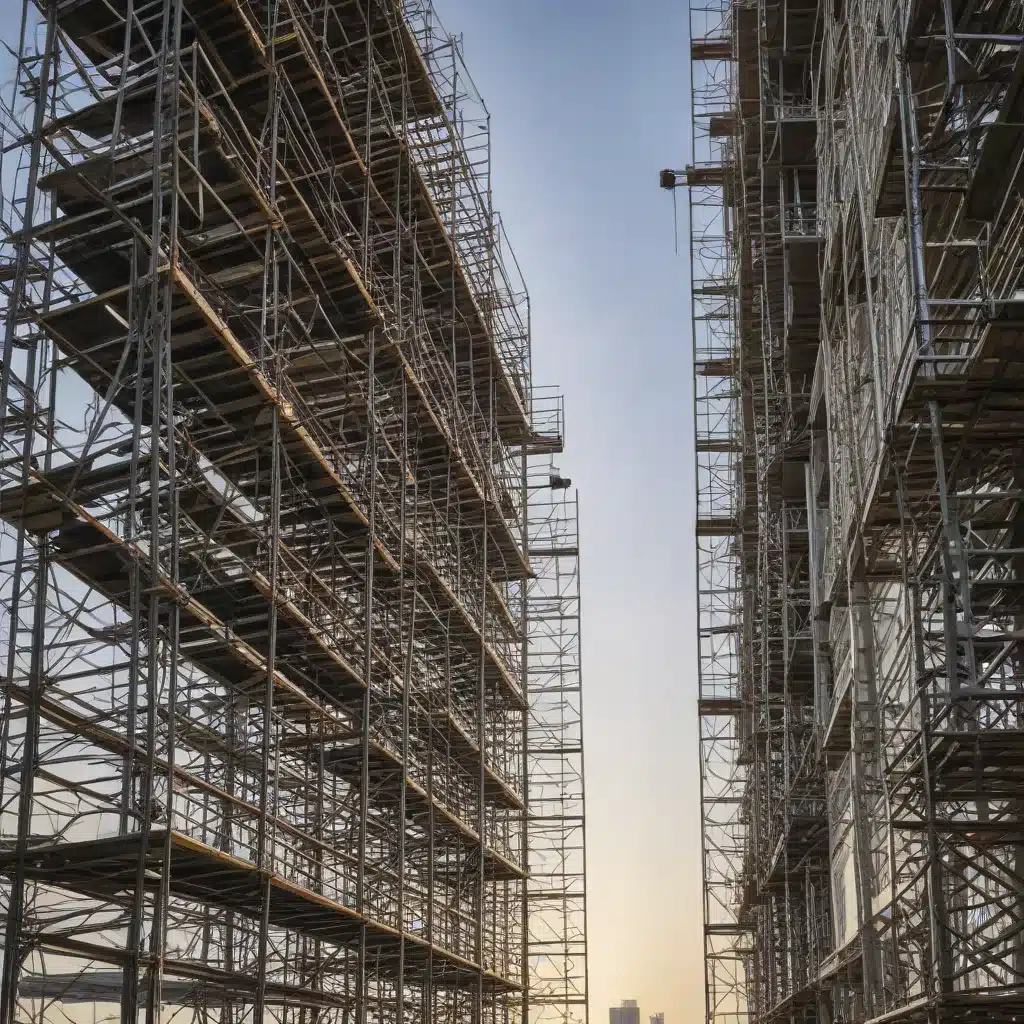

In the dynamic and ever-evolving construction landscape of the United Arab Emirates (UAE), the role of scaffolding suppliers has become increasingly crucial. As the region continues to witness a surge in infrastructure development and real estate projects, the need for reliable, innovative, and cost-effective scaffolding solutions has become paramount. This article delves into the intricacies of navigating the UAE scaffolding market, exploring the best practices, regulatory compliance, and cost management strategies that construction professionals must consider.

Navigating the UAE Scaffolding Landscape

The UAE’s construction industry is governed by a robust set of regulations and standards, with a strong emphasis on worker safety and site efficiency. Scaffolding, as a critical component of any construction project, is subject to stringent guidelines set forth by the UAE’s Ministry of Human Resources and Emiratization (MoHRE) and the Occupational Safety and Health Administration (OSHA) in the UAE.

UAE Ministry of Human Resources and Emiratization (MoHRE) Regulations

OSHA Scaffolding Standards in the UAE

These regulations mandate the use of certified scaffolding equipment, proper installation and dismantling procedures, and the implementation of comprehensive safety measures. Failure to comply with these standards can result in severe penalties and project delays, underscoring the importance of partnering with reputable scaffolding suppliers who have a proven track record of adhering to local regulations.

Evaluating Scaffolding Suppliers

When selecting a scaffolding supplier in the UAE, construction professionals must carefully assess several key factors to ensure a successful and compliant partnership.

Regulatory Compliance

A critical consideration is the supplier’s adherence to local regulations. Reputable suppliers should be able to provide documentation demonstrating their compliance with MoHRE and OSHA guidelines, including certifications for their equipment and personnel. Inquiring about their on-site safety practices and training programs for workers can also provide valuable insights into their commitment to maintaining a safe working environment.

Innovative Scaffolding Solutions

The UAE’s construction industry is constantly evolving, with a growing demand for innovative scaffolding solutions that enhance efficiency and safety. Effective suppliers should be able to offer a diverse range of advanced scaffolding systems, such as modular, cantilever, or suspended platforms, that can be tailored to the unique requirements of each project.

Cost Optimization

Scaffolding costs can significantly impact a construction project’s overall budget, making it crucial to partner with suppliers who prioritize cost optimization. Reputable suppliers should be transparent about their pricing structures, provide detailed cost estimates, and offer flexible rental or purchase options to suit the project’s needs.

To help construction professionals navigate the scaffolding supplier landscape in the UAE, here is a comparison table highlighting the key considerations:

| Consideration | Importance | Evaluation Criteria |

|---|---|---|

| Regulatory Compliance | High | – MoHRE and OSHA certifications – Documented safety protocols – Worker training programs |

| Innovative Solutions | High | – Diverse range of scaffolding systems – Customizable configurations – Advanced safety features |

| Cost Optimization | High | – Transparent pricing structures – Flexible rental or purchase options – Competitive market rates in USD |

By carefully evaluating these factors, construction professionals can identify scaffolding suppliers who are committed to delivering safe, efficient, and cost-effective solutions that align with the UAE’s regulatory landscape.

Best Practices for Scaffolding Deployment

Effective scaffolding deployment is not only a matter of regulatory compliance but also a key driver of project success. By adopting best practices, construction teams can ensure the seamless integration of scaffolding systems while prioritizing worker safety and cost management.

Proper Planning and Design

Careful planning and design of the scaffolding system are crucial to its successful implementation. This includes conducting thorough site assessments, determining the appropriate scaffolding type and configuration, and collaborating with the supplier to develop a comprehensive installation plan. Proactive planning helps identify potential challenges, such as site constraints or access limitations, and enables the construction team to address them effectively.

Emphasis on Safety

The UAE’s construction industry places a strong emphasis on worker safety, and scaffolding deployment is no exception. Best practices include conducting regular inspections, implementing fall protection measures, and providing comprehensive training for workers who will be using the scaffolding. Suppliers should be able to offer guidance on the latest safety equipment and techniques to ensure a secure working environment.

Optimizing Scaffolding Utilization

Maximizing the utilization of scaffolding assets can lead to significant cost savings for construction projects. This can be achieved through strategic planning, effective scheduling, and proactive maintenance. By coordinating with the scaffolding supplier to optimize deployment and minimize downtime, construction teams can optimize their return on investment.

Sustainable Practices

As the UAE continues to prioritize environmental sustainability, construction professionals must also consider the ecological impact of their scaffolding solutions. Partnering with suppliers who offer eco-friendly and recyclable scaffolding materials can contribute to the overall sustainability of the project, aligning with the UAE’s commitment to green building practices.

By adopting these best practices, construction teams can ensure the efficient, cost-effective, and safe deployment of scaffolding systems, ultimately supporting the successful completion of their projects.

Cost Considerations and Strategies

The cost of scaffolding can have a significant impact on a construction project’s overall budget, making it a critical factor for construction professionals to consider. In the UAE, several strategies can be employed to manage and optimize scaffolding costs.

Understanding the Cost Breakdown

Scaffolding costs can be categorized into various components, including equipment rental or purchase, transportation, installation, maintenance, and dismantling. By thoroughly understanding the cost breakdown, construction teams can identify areas for potential savings and negotiate effectively with suppliers.

Rental vs. Purchase Evaluation

Depending on the project’s scope and duration, construction teams may have the option to either rent or purchase scaffolding equipment. Evaluating the long-term costs and benefits of each approach can help identify the most suitable and cost-effective solution. Factors such as project timeline, equipment utilization, and maintenance requirements should be carefully considered.

Negotiating Favorable Rates

Leveraging the competitive nature of the UAE’s scaffolding market, construction teams can negotiate favorable rates with suppliers. This may involve comparing quotes, requesting volume discounts, or exploring alternative financing options, such as leasing or pay-per-use models.

Optimizing Scaffolding Utilization

As mentioned earlier, maximizing the utilization of scaffolding assets can lead to significant cost savings. By coordinating with suppliers to develop efficient deployment and retrieval schedules, construction teams can minimize downtime and ensure that the scaffolding is utilized to its fullest potential.

Considering Innovative Solutions

Embracing innovative scaffolding solutions, such as modular or lightweight systems, can also contribute to cost optimization. These advanced systems may offer enhanced efficiency, faster installation, and reduced material requirements, ultimately resulting in lower overall costs.

By implementing these cost management strategies, construction professionals in the UAE can effectively navigate the scaffolding landscape and ensure that their projects remain within budget while maintaining the highest standards of safety and compliance.

Conclusion

In the dynamic construction industry of the UAE, the role of scaffolding suppliers has become increasingly critical. By fostering collaborative relationships with reputable suppliers who prioritize regulatory compliance, innovative solutions, and cost optimization, construction professionals can ensure the successful and sustainable deployment of scaffolding systems.

Through a comprehensive understanding of the local regulatory landscape, a commitment to best practices, and the implementation of cost-effective strategies, construction teams in the UAE can unlock the full potential of their scaffolding partnerships, ultimately contributing to the successful delivery of their projects.

As the UAE continues to lead the way in infrastructure development and real estate, the importance of reliable and innovative scaffolding solutions will only grow. By embracing the insights and strategies outlined in this article, construction professionals can navigate the UAE scaffolding market with confidence, positioning their projects for success while prioritizing worker safety and cost-effectiveness.

To learn more about https://sherahmedscaffolding.com/ and how we can support your construction project in the UAE, please visit our website or contact us directly.