Navigating Sustainable Scaffolding Solutions in the UAE

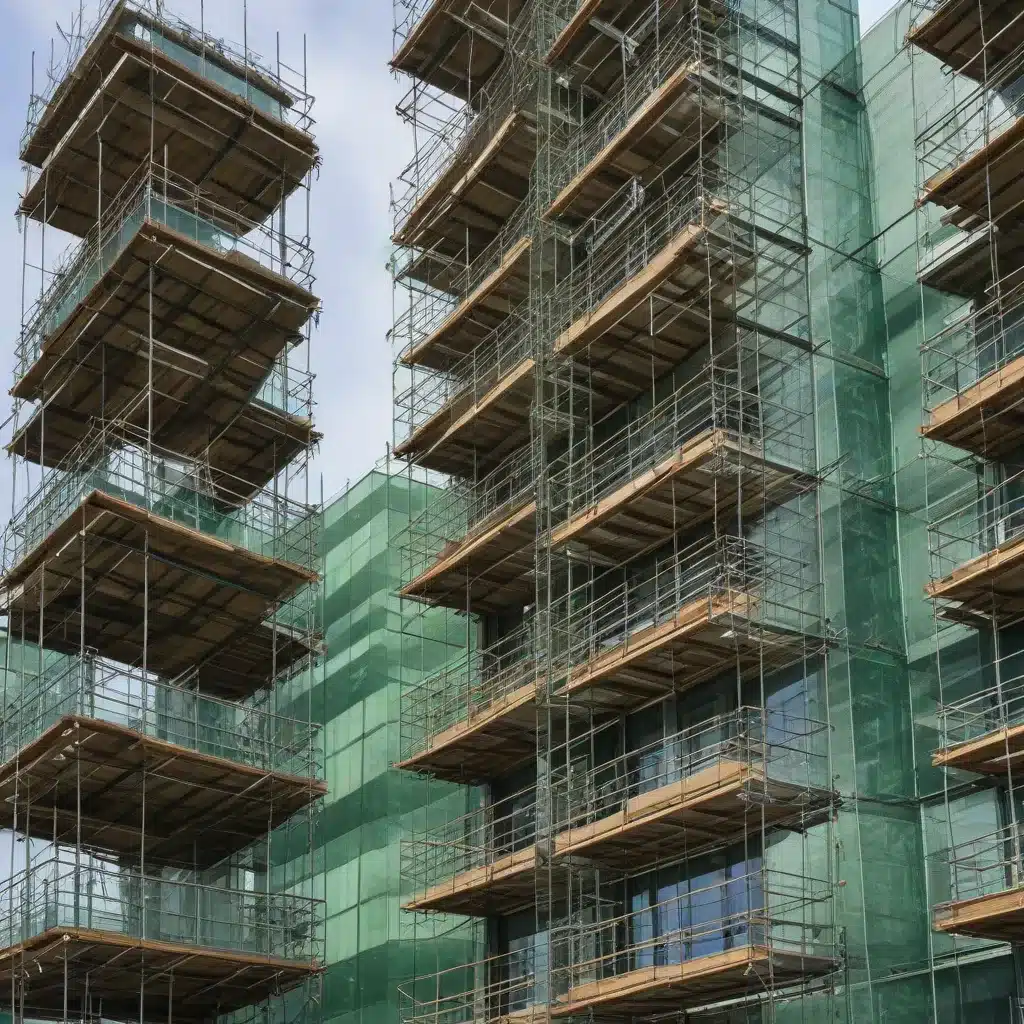

As the construction industry in the United Arab Emirates (UAE) continues to evolve, a growing emphasis on environmental sustainability has become a top priority. Amidst this shift, the role of scaffolding has taken on new significance, as construction companies seek to minimize their ecological footprint while maintaining efficiency, safety, and cost-effectiveness.

In the UAE, regulatory bodies have introduced a range of guidelines and standards aimed at promoting sustainable construction practices. These regulations not only address the environmental impact of construction activities but also mandate the use of eco-friendly materials and technologies, including in the realm of scaffolding. As construction professionals navigate this evolving landscape, understanding the latest developments in sustainable scaffolding solutions has become crucial.

Sher Ahmed Scaffolding, a leading provider of scaffolding services in the UAE, has been at the forefront of this green transition. By embracing innovative practices and staying abreast of the latest regulatory requirements, the company has positioned itself as a trusted partner in delivering sustainable construction solutions.

Eco-Friendly Scaffolding Materials in the UAE

One of the primary aspects of sustainable scaffolding revolves around the selection of eco-friendly materials. Traditionally, scaffolding systems in the UAE have relied heavily on steel and aluminum, which, while durable and recyclable, have a significant carbon footprint due to the energy-intensive production processes.

However, the construction industry in the UAE has witnessed the emergence of alternative materials that offer a more sustainable alternative. Bamboo scaffolding, for instance, has gained traction as a versatile and renewable option. Bamboo, a fast-growing natural resource, is not only lighter than conventional materials but also requires less energy to produce, reducing the overall environmental impact of transportation and assembly.

Another innovative solution gaining popularity in the UAE is the use of recycled polymers and composite materials in scaffolding components. These materials are created from post-consumer plastic waste, effectively diverting waste from landfills and minimizing the demand for virgin resources.

| Material | Sustainability Benefits | Estimated Cost per Square Meter (USD) |

|---|---|---|

| Steel Scaffolding | Durable and recyclable, but energy-intensive production | $20 – $30 |

| Aluminum Scaffolding | Lightweight and recyclable, but high energy consumption in manufacturing | $25 – $35 |

| Bamboo Scaffolding | Renewable, lightweight, and low-energy production | $18 – $25 |

| Recycled Polymer/Composite Scaffolding | Diverts plastic waste from landfills, reduced energy consumption | $22 – $32 |

By embracing these eco-friendly scaffolding materials, construction companies in the UAE can significantly reduce their environmental footprint while maintaining the necessary strength, durability, and cost-effectiveness required for successful projects.

Modular Scaffolding Systems: Minimizing Waste and Maximizing Efficiency

Another key aspect of sustainable scaffolding in the UAE is the adoption of modular scaffolding systems. These innovative solutions are designed to minimize waste and maximize efficiency throughout the construction process.

Modular scaffolding systems consist of interchangeable components that can be easily assembled, disassembled, and reconfigured for different projects or configurations. This approach eliminates the need for cut-to-fit scaffolding, which can generate substantial waste during the installation and removal process.

By streamlining the construction workflow and reducing the demand for new materials, modular scaffolding systems contribute to a more sustainable construction environment in the UAE. Additionally, these systems are designed for long-term use, with a focus on durability and ease of maintenance, further enhancing their environmental credentials.

Sher Ahmed Scaffolding, in compliance with the UAE’s regulations, has integrated modular scaffolding systems into their service offerings, ensuring that their clients benefit from the enhanced efficiency and reduced waste associated with these innovative solutions.

Energy-Efficient Scaffolding Practices in the UAE

Sustainability in scaffolding extends beyond the choice of materials and system design. In the UAE, construction companies are also required to address the energy efficiency of the entire scaffolding lifecycle, from production to installation, use, and dismantling.

One way Sher Ahmed Scaffolding has optimized energy efficiency is through the implementation of smart logistics for the transportation of scaffolding materials. By utilizing advanced software and route planning, the company minimizes fuel consumption and carbon emissions associated with the movement of scaffolding components to and from project sites.

Furthermore, at the construction site itself, Sher Ahmed Scaffolding employs fuel-efficient machinery for the assembly and disassembly of scaffolding systems. This includes the use of modern cranes and other equipment that adhere to the latest energy-saving standards, reducing the overall carbon footprint of the scaffolding operations.

In addition to these measures, the company has also integrated renewable energy sources, such as solar-powered lighting, into their scaffolding setups. These eco-friendly solutions not only provide the necessary site illumination but also contribute to the overall sustainability of the construction project.

Lifecycle Management and Recycling Programs in the UAE

To truly embrace sustainability, construction companies in the UAE must consider the entire lifecycle of their scaffolding systems, from design to end-of-life disposal. Sher Ahmed Scaffolding has implemented comprehensive lifecycle management strategies to ensure the environmental impact of their scaffolding solutions is minimized.

During the design phase, the company carefully evaluates the sustainability credentials of the materials and components used in their scaffolding systems. This includes conducting life cycle assessments to understand the environmental impact of each element, from resource extraction to manufacturing, transportation, and eventual disposal or recycling.

At the end of a scaffolding system’s useful life, Sher Ahmed Scaffolding has established recycling programs to divert the materials from landfills. Components made from metals like steel and aluminum can be easily recycled and reused, contributing to the circular economy. For newer materials, such as bamboo and recycled polymers, the company collaborates with specialized recycling partners to ensure these resources are repurposed or recycled effectively.

By implementing these lifecycle management practices, Sher Ahmed Scaffolding not only minimizes waste but also promotes the efficient use of resources, aligning with the UAE’s regulatory requirements and demonstrating a commitment to environmental responsibility.

Regulatory Compliance and Safety Standards in the UAE

In the UAE, the construction industry is subject to a robust set of regulations and safety standards that govern the use of scaffolding systems. Compliance with these regulations is not only a legal requirement but also a crucial aspect of ensuring the safety and well-being of construction workers and the general public.

The UAE’s Code of Practice for the Safe Use of Scaffolding, issued by the Ministry of Infrastructure Development, outlines the comprehensive guidelines and specifications that all scaffolding providers must adhere to. These regulations cover a wide range of aspects, including:

- Material Specifications: Mandating the use of high-quality, corrosion-resistant materials for scaffolding components.

- Load-bearing Capacity: Ensuring scaffolding systems are designed to support the intended loads, including materials, equipment, and personnel.

- Anchorage and Stability: Requiring proper anchoring and bracing to maintain the stability and structural integrity of the scaffolding.

- Access and Egress: Establishing standards for safe access and egress points, including the use of ladders, stairs, and platforms.

- Fall Protection: Mandating the use of safety harnesses, guardrails, and other fall prevention measures to safeguard workers.

- Inspection and Maintenance: Requiring regular inspections and timely maintenance to ensure the continued safety and reliability of the scaffolding.

Sher Ahmed Scaffolding, as a leading provider in the UAE, has meticulously aligned its operations and services with these regulatory requirements. The company’s commitment to safety and compliance is evident in its rigorous training programs, quality assurance processes, and ongoing collaboration with regulatory authorities to stay abreast of the latest developments.

Cost Management Strategies for Sustainable Scaffolding in the UAE

While sustainability is a crucial consideration, construction companies in the UAE must also navigate the financial aspects of their projects. Sher Ahmed Scaffolding has developed a range of cost management strategies to ensure that their sustainable scaffolding solutions remain economically viable for their clients.

One of the key strategies employed by the company is the optimization of material usage. By carefully selecting eco-friendly materials, such as bamboo and recycled polymers, Sher Ahmed Scaffolding is able to provide cost-effective alternatives to traditional steel and aluminum scaffolding, as shown in the earlier cost comparison table.

Additionally, the company’s adoption of modular scaffolding systems contributes to cost savings by minimizing material waste, streamlining the construction process, and reducing the need for on-site modifications or adjustments.

Sher Ahmed Scaffolding also leverages economies of scale to offer competitive pricing to its clients. By maintaining a diverse fleet of eco-friendly scaffolding equipment and establishing strategic partnerships with suppliers, the company is able to negotiate favorable rates and pass on the savings to its customers.

Furthermore, the company’s emphasis on energy efficiency and the integration of renewable energy sources, such as solar-powered lighting, helps to reduce the ongoing operational costs associated with scaffolding deployment, ultimately enhancing the overall cost-effectiveness of their sustainable solutions.

Conclusion

As the construction industry in the UAE continues to prioritize environmental sustainability, the role of scaffolding has become increasingly crucial in shaping a greener future. Through the adoption of eco-friendly materials, modular design principles, energy-efficient practices, and comprehensive lifecycle management strategies, construction companies like Sher Ahmed Scaffolding are leading the charge towards sustainable construction.

By adhering to the latest regulatory requirements, safety standards, and cost-management best practices, Sher Ahmed Scaffolding has positioned itself as a trusted partner in delivering innovative and environmentally conscious scaffolding solutions. As the UAE’s construction landscape evolves, the company’s commitment to sustainability will continue to play a pivotal role in reducing the industry’s carbon footprint and paving the way for a more sustainable built environment.