Embracing Technological Advancements for Safer and More Efficient Scaffolding

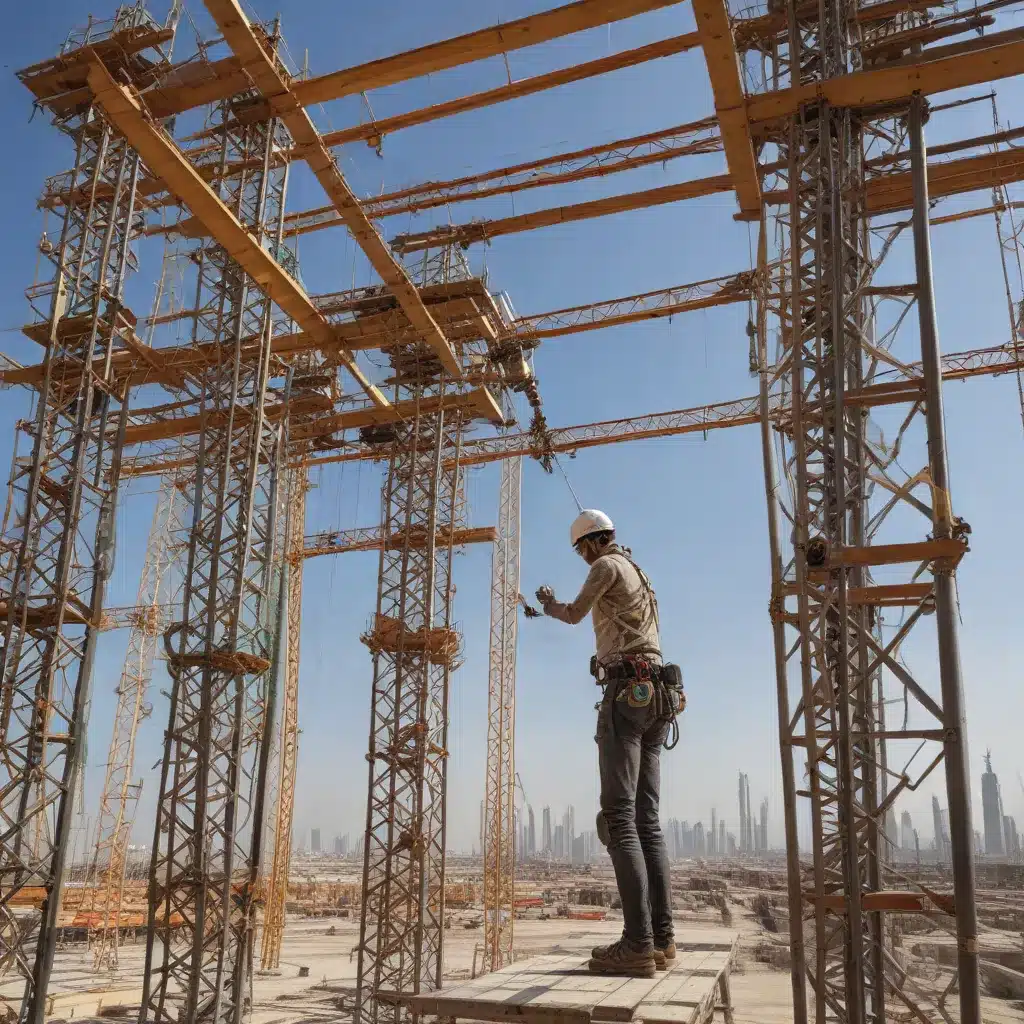

The construction industry in the United Arab Emirates (UAE) has long been known for its ambitious projects and the constant pursuit of innovation. As the nation continues to evolve, the demand for safer, more efficient, and cost-effective scaffolding solutions has become increasingly crucial. In this article, we’ll explore how the UAE construction industry is embracing automation and robotics to revolutionize the way scaffolding is deployed, maintained, and dismantled.

Regulatory Landscape: Ensuring Compliance and Safety

The UAE has a robust set of regulations governing the use of scaffolding in construction projects. The Ministry of Human Resources and Emiratisation (MOHRE) has established detailed guidelines and standards that must be adhered to by all construction companies operating within the country.

These regulations cover a wide range of aspects, including the design and installation of scaffolding, the use of appropriate safety equipment, and the training and certification of workers. Failure to comply with these regulations can result in hefty fines and potential project delays, underscoring the importance of staying up-to-date with the latest requirements.

In recent years, the UAE government has taken a proactive approach to promoting safety in the construction industry. The introduction of initiatives such as the Occupational Safety and Health (OSH) system has further reinforced the need for construction companies to prioritize worker safety and adhere to best practices.

Embracing Automation and Robotics: Enhancing Efficiency and Safety

As the UAE construction industry continues to evolve, the adoption of automated and robotic scaffolding solutions has become a key focus area. These advanced technologies offer a range of benefits, including improved efficiency, enhanced safety, and cost savings.

Automated Scaffolding Installation and Dismantling:

One of the most significant advancements in the UAE construction industry is the use of automated scaffolding systems. These systems, which can be operated remotely, allow for the rapid and precise installation and dismantling of scaffolding structures. This not only reduces the time and labor required for these tasks but also minimizes the risk of human error, resulting in safer working conditions.

Robotic Inspection and Maintenance:

Robotic platforms equipped with advanced sensors and cameras are now being deployed to inspect and maintain scaffolding structures. These robots can perform routine checks, identify potential issues, and relay real-time data to site managers, enabling proactive maintenance and ensuring the continued safety and stability of the scaffolding.

Augmented Reality (AR) and Virtual Reality (VR) for Training:

The integration of AR and VR technologies into scaffolding training programs has revolutionized the way workers learn and prepare for their tasks. These immersive simulations allow trainees to experience various scenarios, practice safe techniques, and familiarize themselves with the latest regulations and best practices without the need for physical scaffolding structures.

Sensor-Driven Monitoring and Analytics:

Construction companies in the UAE are increasingly leveraging IoT-enabled sensors and data analytics to monitor the performance and condition of their scaffolding systems. By collecting and analyzing data on factors such as load, stress, and environmental conditions, these advanced systems can provide valuable insights that support predictive maintenance, safety assessments, and optimized resource allocation.

Cost Management Strategies: Maximizing Return on Investment

The implementation of automated and robotic scaffolding solutions in the UAE construction industry comes with a range of cost implications. While the initial investment may be higher, the long-term benefits can result in significant cost savings and a better return on investment.

Reduced Labor Costs:

The use of automated and robotic systems for scaffolding installation, inspection, and maintenance can dramatically reduce the need for manual labor, leading to substantial cost savings. This is particularly relevant in the UAE, where labor costs have been steadily increasing due to the high demand for skilled workers in the construction sector.

Improved Efficiency and Reduced Downtime:

Automated and robotic scaffolding solutions can significantly improve the efficiency of construction projects, reducing the time required for the setup, inspection, and dismantling of scaffolding structures. This, in turn, can lead to faster project completion and fewer instances of costly project delays, ultimately improving the overall profitability of the construction endeavor.

Enhanced Safety and Reduced Liability:

By prioritizing worker safety through the implementation of advanced scaffolding technologies, construction companies in the UAE can potentially reduce the risk of accidents and the associated legal and financial liabilities. This not only benefits the well-being of the workforce but can also result in lower insurance premiums and a stronger reputation within the industry.

Sustainable Materials and Practices:

Many of the automated and robotic scaffolding solutions being adopted in the UAE construction industry are designed with sustainability in mind. This includes the use of lightweight, durable materials that can be reused and recycled, as well as the implementation of energy-efficient practices during the installation and dismantling processes. These sustainable practices can lead to long-term cost savings and contribute to the UAE’s broader environmental goals.

Innovation in Scaffolding: Trends and Developments

As the UAE construction industry continues to evolve, the scaffolding sector has witnessed a surge of innovative solutions and practices. From modular and adaptable scaffolding systems to the integration of 3D printing and advanced materials, the industry is constantly pushing the boundaries of what is possible.

Modular and Adaptable Scaffolding:

The development of modular and adaptable scaffolding systems has gained traction in the UAE construction industry. These solutions allow for the quick and efficient reconfiguration of scaffolding structures to accommodate changing project requirements, reducing the need for complete dismantling and rebuilding.

Lightweight and High-Strength Materials:

The use of advanced materials, such as carbon fiber and aluminum alloys, has become increasingly prevalent in the UAE’s scaffolding industry. These materials offer a combination of strength, durability, and reduced weight, enabling the construction of more efficient and safer scaffolding structures.

3D Printing and Prefabrication:

The integration of 3D printing and prefabrication technologies has the potential to revolutionize the scaffolding industry in the UAE. These advancements allow for the rapid prototyping and customization of scaffolding components, reducing lead times and minimizing waste during the construction process.

Integrated Monitoring and Control Systems:

The UAE construction industry is embracing the power of integrated monitoring and control systems to enhance the management and safety of scaffolding structures. These systems leverage a range of sensors, smart controllers, and cloud-based platforms to provide real-time data and enable remote monitoring and adjustments, ensuring optimal performance and compliance with safety standards.

Conclusion: Embracing the Future of Scaffolding

As the UAE construction industry continues to push the boundaries of innovation, the scaffolding sector has emerged as a key area of focus. By embracing automated and robotic solutions, construction companies in the UAE are reaping the benefits of enhanced efficiency, improved safety, and cost savings.

The adoption of these advanced technologies is not only a testament to the industry’s commitment to progress but also a reflection of the UAE’s broader vision for a sustainable and technologically advanced built environment. As construction professionals in the UAE navigate the evolving landscape of scaffolding regulations and best practices, the integration of automation and robotics will undoubtedly play a crucial role in shaping the future of the industry.

To stay at the forefront of these advancements, construction companies in the UAE must remain vigilant, continuously educate their workforce, and collaborate with industry leaders and regulatory bodies. By embracing the transformative power of technology, the UAE’s scaffolding industry can pave the way for a safer, more efficient, and more cost-effective construction landscape, firmly cementing the nation’s position as a global leader in the built environment.