Revolutionizing Scaffolding Practices: Embracing Safety and Cost-Efficiency

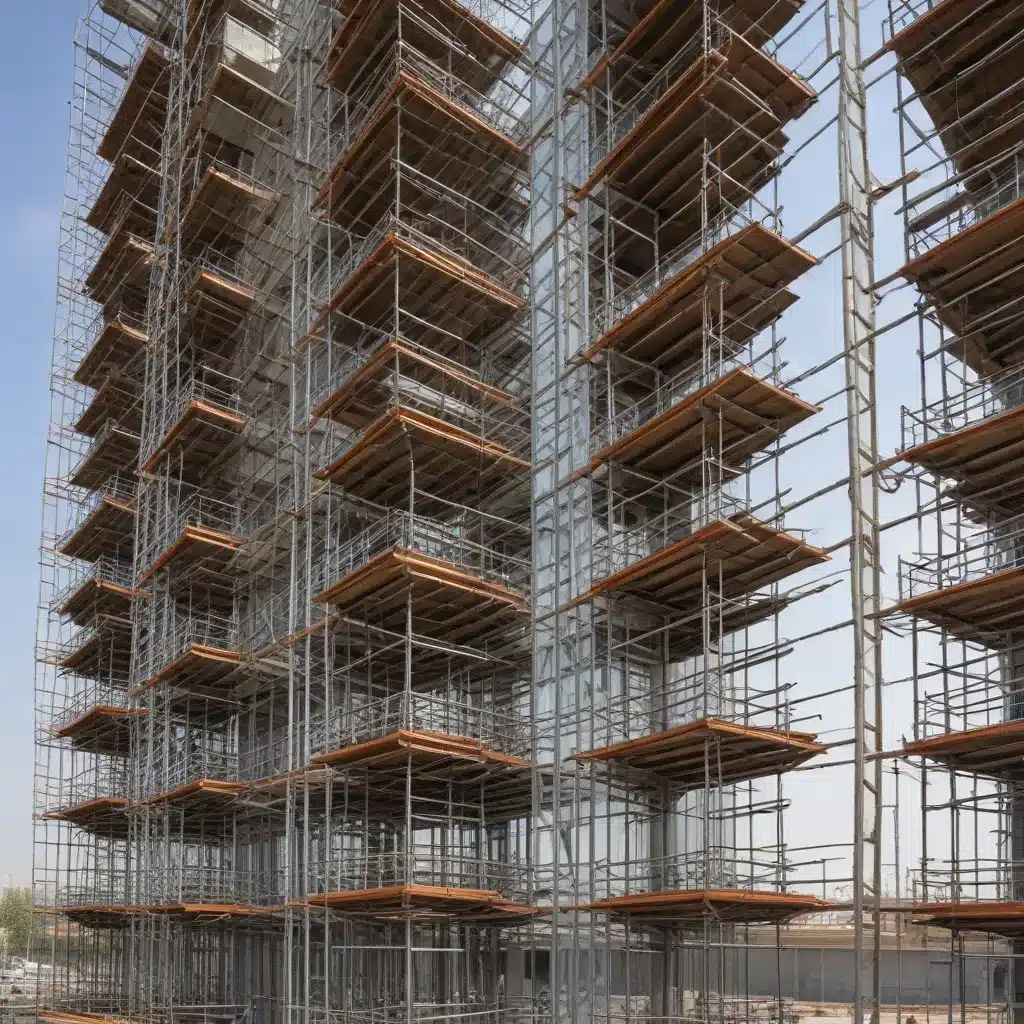

In the dynamic construction landscape of the United Arab Emirates, the adoption of innovative scaffolding solutions has become a crucial driver for enhancing safety, improving productivity, and optimizing costs. As the industry evolves, construction professionals in the UAE are increasingly recognizing the importance of staying abreast of the latest advancements in scaffolding technology and regulations.

Navigating the UAE’s Scaffolding Regulations

The UAE has established a comprehensive set of regulations and standards to ensure the safety and well-being of construction workers and the public. These regulations, enforced by the Ministry of Human Resources and Emiratisation (MOHRE), cover a wide range of aspects, from the design and installation of scaffolding systems to the mandatory use of personal protective equipment (PPE).

One of the key regulations in the UAE is the requirement for all scaffolding structures to be designed and certified by a licensed professional engineer. This ensures that the structural integrity and load-bearing capacity of the scaffolding meet the stringent safety requirements. Additionally, construction companies are mandated to provide comprehensive training to their workers on the proper use and maintenance of scaffolding, further emphasizing the importance of safety in the industry.

Innovative Scaffolding Solutions: Enhancing Safety and Efficiency

In response to the evolving regulatory landscape and the growing demand for safer and more efficient construction practices, the UAE’s scaffolding industry has witnessed a surge in innovative solutions. These advancements focus on enhancing worker safety, improving productivity, and optimizing costs, all while maintaining compliance with local regulations.

Modular Scaffolding Systems

One of the prominent innovations in the UAE’s scaffolding industry is the widespread adoption of modular scaffolding systems. These prefabricated, interlocking components allow for quick and secure assembly, reducing the time and labor required for installation. Modular systems also offer enhanced stability and load-bearing capacity, providing a safer working environment for construction professionals.

Cost Comparison: Modular vs. Traditional Scaffolding

| Metric | Modular Scaffolding | Traditional Scaffolding |

|---|---|---|

| Installation Time | 25-30% faster | Longer setup time |

| Material Costs | 15-20% higher | Lower initial investment |

| Maintenance Costs | 20-25% lower | Higher maintenance requirements |

| Overall Cost (per project) | 10-15% lower | Higher overall project costs |

The cost savings associated with modular scaffolding systems can be attributed to their reusability, reduced labor requirements, and lower maintenance expenses. This makes them a compelling choice for construction companies seeking to optimize their budgets while maintaining safety standards.

Automated Climbing Scaffolding

Another innovative solution that is gaining traction in the UAE is automated climbing scaffolding. These systems are equipped with motorized mechanisms that allow the scaffolding to automatically adjust its height as the building progresses, eliminating the need for manual adjustments and reducing the risk of worker injuries.

Automated climbing scaffolding offers several advantages, including:

– Improved Safety: The automated system reduces the need for workers to manually dismantle and reassemble the scaffolding, minimizing the risk of falls and other accidents.

– Enhanced Productivity: By automating the height adjustment process, construction teams can complete tasks more efficiently, leading to faster project turnaround times.

– Cost-Effectiveness: The reduced labor requirements and improved efficiency associated with automated climbing scaffolding can result in significant cost savings over the course of a project.

The adoption of these advanced scaffolding solutions in the UAE has contributed to a notable improvement in construction safety and productivity, positioning the industry for a more sustainable and innovative future.

Scaffolding Safety Equipment and Training

In addition to the advancements in scaffolding technology, the UAE has also placed a strong emphasis on worker safety through the mandatory use of personal protective equipment (PPE) and comprehensive training programs.

Personal Protective Equipment (PPE)

Under the UAE’s construction safety regulations, workers on scaffolding sites are required to wear the following PPE:

– Hard Hats: Protective headgear to guard against falling objects and head injuries.

– Safety Harnesses: Fall arrest systems that secure workers to the scaffolding structure, preventing falls from height.

– Protective Gloves: Cut-resistant gloves to protect hands from sharp edges and pinch points.

– Safety Boots: Slip-resistant, reinforced footwear to prevent foot injuries.

– High-Visibility Clothing: Brightly colored vests or jackets to enhance worker visibility on the construction site.

The cost of providing this essential PPE is typically included in the overall project budget, with construction companies responsible for ensuring that their workers are equipped with the necessary safety gear.

Scaffolding Safety Training

To ensure that construction workers in the UAE are well-versed in the safe operation and maintenance of scaffolding, the MOHRE requires all personnel involved in scaffolding activities to undergo comprehensive training. This training covers topics such as:

– Scaffolding Assembly and Disassembly: Proper techniques for erecting, modifying, and dismantling scaffolding structures.

– Load-Bearing Capacity: Understanding the weight limitations and safe working loads of different scaffolding components.

– Fall Protection: Proper use of safety harnesses, lanyards, and other fall arrest systems.

– Hazard Identification: Recognizing and mitigating potential risks associated with scaffolding, such as unstable foundations or electrical hazards.

– Maintenance and Inspection: Regularly inspecting scaffolding for any damage or defects and performing necessary maintenance.

The scaffolding safety training is typically provided by certified instructors or training centers, ensuring that construction workers in the UAE are equipped with the knowledge and skills to work safely on scaffolding sites.

Cost Management Strategies for Scaffolding Projects

While the implementation of innovative scaffolding solutions and safety measures is crucial, construction companies in the UAE must also strategically manage their project costs to remain competitive and profitable. By adopting effective cost management strategies, these companies can optimize their scaffolding investments and maximize their returns.

Rental vs. Purchase of Scaffolding

One of the key decisions construction companies face is whether to rent or purchase their scaffolding equipment. The choice between these two options depends on factors such as the project’s duration, the frequency of scaffolding use, and the company’s capital investment capabilities.

Rental Costs:

– Short-term projects (less than 6 months): Renting scaffolding can be more cost-effective, as it eliminates the need for upfront capital investment and ongoing maintenance expenses.

– Estimated rental cost: $5-$10 per square meter of scaffolding per month.

Purchase Costs:

– Long-term projects (more than 12 months) or companies with frequent scaffolding needs: Purchasing scaffolding equipment can be more economical in the long run, as it provides greater flexibility and control over the assets.

– Estimated purchase cost: $100-$150 per square meter of scaffolding.

By carefully analyzing their project requirements and financial resources, construction companies in the UAE can make an informed decision on the most cost-effective approach to scaffolding procurement.

Preventive Maintenance and Asset Management

Regardless of whether construction companies choose to rent or purchase their scaffolding equipment, implementing a robust preventive maintenance program is crucial for cost optimization. Regular inspections, cleaning, and timely repairs can extend the lifespan of the scaffolding, reduce the frequency of replacements, and minimize downtime during construction projects.

Furthermore, effective asset management strategies, such as centralized inventory tracking and efficient logistics, can help construction companies identify opportunities for cost savings. By optimizing the utilization and deployment of their scaffolding assets, companies can reduce waste, minimize rental expenses, and improve overall project profitability.

Embracing the Future of Scaffolding in the UAE

As the construction industry in the UAE continues to evolve, the adoption of innovative scaffolding solutions, adherence to safety standards, and the implementation of cost-effective practices will be instrumental in shaping the future of the sector. By staying ahead of the curve and embracing these advancements, construction companies in the UAE can position themselves for long-term success and contribute to the overall growth and development of the nation’s built environment.

To explore the comprehensive range of scaffolding services and cost-effective solutions available in the UAE, visit https://sherahmedscaffolding.com/, a leading provider dedicated to enhancing safety, productivity, and project profitability.